Excavator Attachments with Versatility and Profitability:

Construction and land management have been known as industries that follow the principle of “one machine, one job” for a long time with outstanding American excavator attachments. But everything has changed because of the new market demands.

Having a fleet of machines with specialized functions is no longer enough if each of them is not used in the most efficient way. And this is where the right excavator attachments really matter. By completely changing the character of the standard excavator to that of a multi-purpose versatile tool, they first of all make a worker save a lot of time and as a result increase his profit to an unthinkable level.

The Era of Specialization is Over

The point of view of the industry now is that machines with versatile, multi-functional can be used to solve the problem rather than relying on those with single purpose only.

The purchase of quality parts from a reputable source such as American Excavator is beneficial in that a single equipment can now tackle the wide range of jobs easy like demolition and land clearing.

Such a measured turn keeps the unequipped hours of the vehicles minimum, apart from this it lowers the operational costs, and makes a tremendous impact on the positive cash flow in the business activities of a firm.

The Foundation of Versatility: Understanding the Right Excavator Attachments

An excavator’s true power lies in its ability to adapt. Selecting the most appropriate attachments for an excavator is the first point we should understand to make it a highly versatile machine. From hydraulic breakers to grabs and shredders, each attachment is made of the one material with which it can do the given job without harming the material. The main thing is to pick such attachments that will be enough to handle all the set of tasks, which are the everyday business of your company, so it will be your excavator to be the one that will face the next challenge.

Hydraulic Hammers: Just for instance to make it clear, they are used for demolishing new concrete, rocks, etc which ultimately gives the machine the ability to a comprise breaker.

Grapples: Imagine that you want to move materials quickly and easily, then these tools are the best choices for you as they allow you to do such things as debris, logs, or scrap metal without much help thus saving you a lot of time which in turn leads to more productivity on that clean-up and sorting jobs.

Mulchers/Brush Cutters: By using these machines, it is possible to make land clearing a one-pass operation only with the help of the machines which are capable of shredding the trees and brush into proper sizes and the rest of the material can be used for the forestry and agricultural projects as a valuable source of renewable materials.

The Multi-Tasking Excavator Attachments in Action

Visualize the scenario of a site where only one machine is involved but performs all the tasks necessary from one job to the next, of course, not manually but with a series of rapid change attachments.

- Morning: Starts working with a hydraulic hammer on the basis of power used to break old concrete foundations.

- Afternoon: Replaces the former tool with a grapple in order to collect the demolition debris and truck it for further transportation and disposal.

- Late Afternoon: A trenching bucket is mounted to dig the new foundation footings with the same operator and the same machine.

With such a scenario in the real world, the point shows how versatile the power can be and how one single vehicle can accomplish multiple jobs in a day to such an extent that the use of other vehicles is no longer required.

The Financial Equation:

Maximizing Efficiency for Excavator Attachments ROI

In fact, users of excavators will know that one of the great reasons why they are so awesome is how much the user gets it back in the ROI. Whereas initially, the price of the accessory may be significant, it is still just one-tenth of the price of a new machine used for a single job only.

Moreover, the company would only experience financial gains. Such gains would include: the capacity of work without interruption would expand, less number of workers will be needed hence labor costs will drop and more number of jobs will be carried out using the same machine fleet.

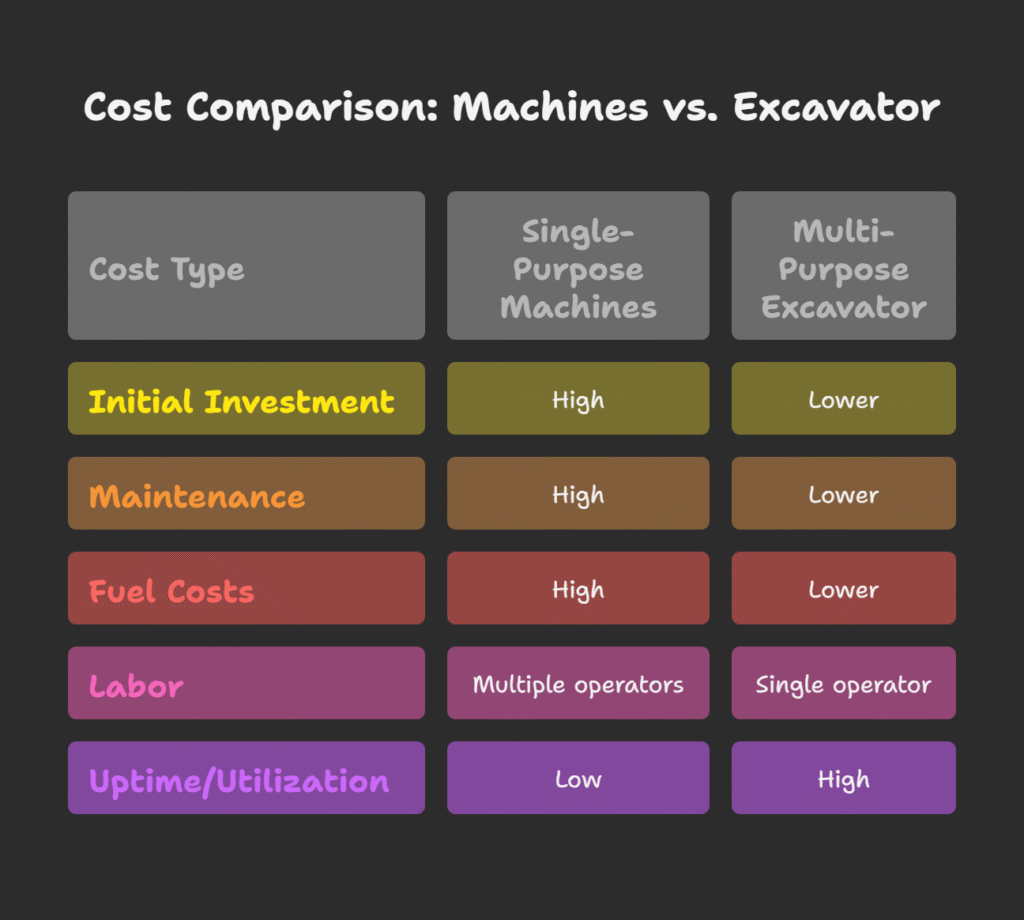

Here is a simple financial breakdown:

| Cost Type | Single-Purpose Machines (e.g., a dedicated jackhammer unit, a separate grapple loader) | Multi-Purpose Excavator with Attachments |

| Initial Investment | High (multiple machines) | Lower (one excavator + attachments) |

| Maintenance | High (multiple engines, tracks, etc.) | Lower (one machine to maintain) |

| Fuel Costs | High (running multiple machines) | Lower (one engine) |

| Labor | Multiple operators required | Single operator can handle multiple tasks |

| Uptime/Utilization | Machines may sit idle for certain jobs | High utilization as machine can perform many jobs |

Conclusion: A Strategic Investment in Your Business

The most successful businesses in today’s fiercely competitive market are those which are capable of achieving more with less. You are certainly not just purchasing a tool by taking on the flexibility and the effectiveness that American excavator extensions offer you; on the contrary, you are making a strategic move in the business-’s future.

- A simple step as equipping your excavator with a variety of attachments can act as a catalyst for greater project flexibility, higher profits, and a stronger presence in the market.

- Excavator Attachments are not just tools; they are a strategic asset that increases your operational flexibility.

- The long-term savings in maintenance, labor, and fuel costs far outweigh the initial investment.

- Through opting for top-notch, American-made, attachments which are part of your equipment, you are making sure the durability and performance are preserved and deliver a remarkable excavator ROI for years to come.

FAQs

How do excavator attachments improve efficiency?

A single machine is enabled to do multiple jobs at once by attachments. Hence there is no need to interrupt the flow and change the machine. What is more, a great amount of time is saved on switching the machine in and out of the job site.

What is the ROI on excavator attachments?

The ROI is tremendous as the company saves on the labor, maintenance, and fuel costs and, at the same time, becomes more flexible in taking on various types of jobs.

What are the most popular excavator attachments?

The most widely used accessories are buckets, hydraulic hammers, grapples, and mulchers, and every single one of them performs a critical function.

Are all excavator attachments compatible with my machine?

Compatibility is influenced by the make, the model, as well as the size of your excavator. Numerous attachments are equipped with a quick coupler system for effortless changes.

How long does it take to change an attachment?

By using a contemporary quick coupler system, the time for changing an attachment can be as short as a few minutes.

Can a single operator manage multiple excavator attachments?

Yes, a single operator by simply changing the attachment on his machine can perform multiple-manage tasks efficiently.

Why choose American-made excavator attachments?

For a fact, American-made attachments are the result of a high-precision process, which include well-selected materials, quality-controlled and are engineered to last under the most challenging conditions of the work site.