Excavators stand as the backbone of the construction and mining industries, known for their adaptability and effectiveness across various tasks. However, the true potential of these machines is unlocked through a plethora of attachments designed to suit specific needs and scenarios. In this guide, we delve into the significance of excavator attachments and explore the diverse types available, each contributing to enhanced productivity and precision on job sites.

Importance of Excavator Attachments:

Excavator attachments play a pivotal role in boosting productivity, efficiency, and versatility in construction endeavors. Ranging from buckets to breakers, these attachments offer specialized functionalities that empower operators to accomplish tasks with precision and ease. By selecting the appropriate attachment, operators can optimize workflow, minimize downtime, and streamline operations significantly.

For instance, utilizing a trenching bucket for digging trenches or a hydraulic hammer for breaking concrete enhances efficiency compared to using a standard bucket alone. These attachments not only facilitate smoother operations but also reduce manual labor and the necessity for additional machinery, thereby saving both time and costs while maximizing excavator utilization.

Learn More: GUIDE TO THE DIFFERENT TYPES AND SIZES OF EXCAVATORS

Types of Excavator Attachments:

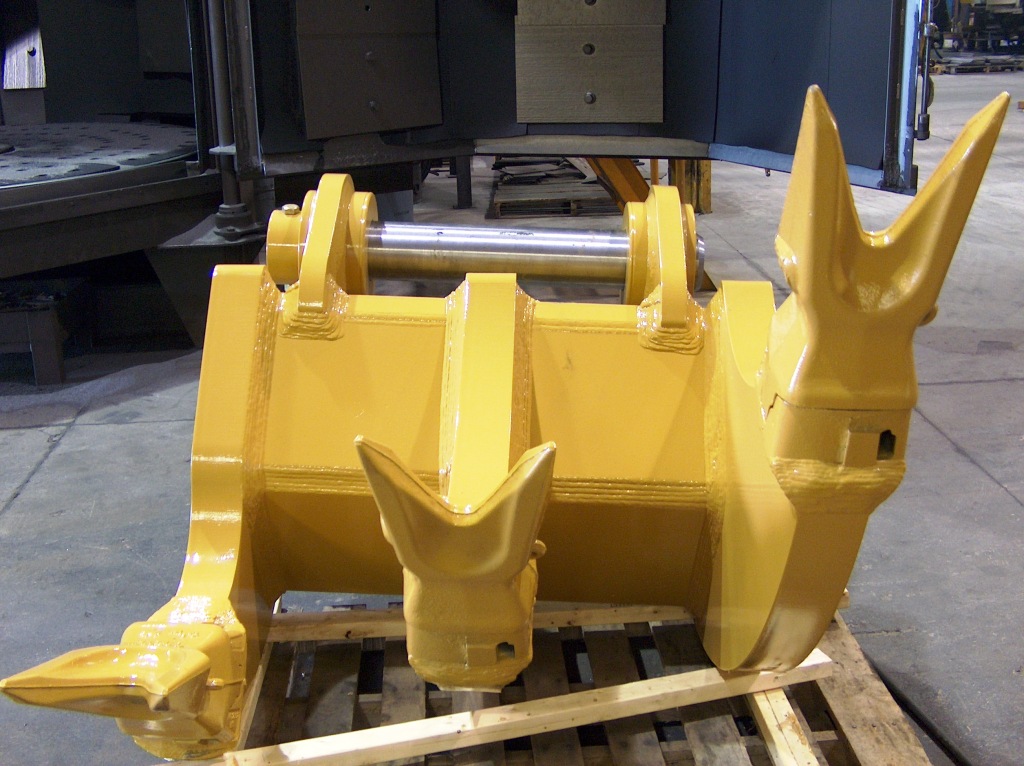

Buckets:

General-purpose buckets cater to digging and loading operations. Rock buckets are specialized for handling rigid materials like stone and concrete.

Rock Breaker (Hydraulic Hammer):

Vital for demolition, quarrying, and road construction projects, providing efficient and precise breaking capabilities.

Quick Coupler:

Enables rapid interchange of attachments, enhancing operational efficiency by facilitating quick switches between various tools.

Clamshell Bucket:

Ideal for precise material handling and excavation in confined spaces, adept at grasping and lifting soil, gravel, and debris.

Orange Grapple:

Versatile for handling bulky materials such as logs, scrap metal, and debris, offering excellent maneuverability and control.

Auger:

Used for drilling holes in the ground, catering to various purposes like installing fence posts, foundations, and utility poles.

Ripper:

Specialized in breaking up hard-packed soil, asphalt, and frozen ground, essential for excavation, grading, and site preparation tasks.

Electromagnet:

Employed in lifting and moving ferrous materials such as scrap metal, rebar, and steel beams, providing efficient material handling solutions in recycling yards, demolition sites, and steel mills.

Learn More: THE MOST POPULAR MANUFACTURERS OF EXCAVATORS

Conclusion:

Excavator attachments are indispensable assets that enhance the capabilities of these workhorses in the construction and mining sectors. By understanding their importance and exploring the diverse types available, operators can maximize efficiency, productivity, and versatility on job sites. Whether it’s digging, breaking, lifting, or drilling, there’s an excavator attachment tailored to meet every need, ensuring successful project execution with precision and ease.