Top 5 Signs You Must Change Your Hydraulic Arm Cylinder

An excavator can be considered as the most important heavy machine on any construction site. The power and accuracy of the machine are mostly dependent on the condition of its hydraulic system, especially the hydraulic arm cylinder which makes the decision of choosing between hydraulic arm cylinder replacement or repair.

The component is the one that is being pressed the most and is under constant stress, so it is, therefore, the most frequent places for friction and the least of the machine parts that eventually wear out. If the warning signs of a failing cylinder are overlooked, it can break down the system in a very catastrophic way, lead to expensive downtime, and be a source of significant safety hazards.

For people who run operations through organizations such as AmericanExcavator.org, unexpected downtime minimization is very important for profitability and project timelines. Learning and understanding the top signs when your hydraulic arm cylinder is about to be changed—not just repaired—is very important for every operator and maintenance manager.

Top 5 Signs For Hydraulic Arm Cylinder Replacement:

1. External Fluid Leaks and Weeping Seals

Among the different types of suffering of the hydraulic cylinder, fluid leaks is the indicator that most people refuse to notice, in fact, they are very obvious. Even though a minor leak may look harmless, it still shows that the seals which are installed for the containment of the high-pressure fluid are broken.

- A leak is a situation when hydraulic fluid is allowed to flow out; at the same time, contaminants such as dirt, dust, and water may be sucked into the system, thereby creating a continuous cycle of increased wear and tear and internal damage.

- A persistent pool of hydraulic fluid under the arm or a permanent wetness around the cylinder’s rod end is a clear indication of major seal failure, which usually requires a full cylinder overhaul or replacement, in case the piston rod is also scored.

- The existence of weeping or dripping liquid at the rod seal, especially after the cylinder has been resting for a short period, indicates that the main barrier is deteriorating, which causes a gradual loss of system pressure and efficiency.

- Besides external leaks, internal leakage, or “blow-by,” is when fluid goes around the piston seal inside the cylinder. It is invisible, but can be detected by irregular movement and is a serious sign of wear inside that part, thus, it requires immediate intervention.

- If there are external leaks, it is very important to check the piston rod for possible damages. Any scratches, nicks, or scoring on the highly-polished chrome surface will tear up new seals almost right away. So, replacing the seals alone is only a temporary solution, if the rod is deeply scored then you have to replace the whole cylinder assembly (or at least the rod and seal kit) to regain the lost sealing capability.

2. Sluggish, Jerky, or Inconsistent Operation

The hydraulic system working properly is an attribute of the smooth, strong, and instant reaction to the given commands of the operator. Any departure from this norm i.e. the decrease in speed to such an extent that it is noticeable, jerky movements (usually referred to as “juddering” or “slip-stick”), or failure to stabilize the position under load (drift) are strong indications that the hydraulic arm cylinder is about to die. Such a deterioration of the device directly affects the company’s productivity and the safety of the working environment.

- Slow Operation and Reduced Force: If the arm of an excavator is going to move slowly than it was before without you understanding the reason, or if the lift of some load you have already done in the past, but this time it is difficult for the machine to do so, this is a clear sign of internal leakage of the cylinder. The pressurized fluid is allowed to go around the piston seals which have been worn, so this is why the force that is effective for the arm is reduced.

- Juddering or Erratic Movement: The symptoms of jerky, uneven, or stuttering movement during cylinder extension or retraction point to increased internal friction or the “stick-slip” phenomenon. The most likely causes can be seals that are worn, contamination in the fluid, or even a bent piston rod that is binding against the gland, these factors accelerate the transition from a smooth, controlled stroke of the cylinder to an abrupt one.

- Cylinder Drift or Creep: If the arm cannot still positioned by the cylinder and slowly drifts downward or inward while the controls are at rest, this is the sign of extreme internal bypass past the piston seals. Apart from that, it is the most critical safety issue and an indirect indication of the loss of the ability of the cylinder to hold the required position during static load.

This reduction of performance is not just in the way of convenience only; it may also be a sign that the other parts of the hydraulic system, such as the pump, are forced to work extra thereby leading to their premature wear as well.

3. Unusual Noises and Vibrations

Normal hydraulic systems produce a steady and recognizable hum. The appearance of strange, loud, and/or persistent sounds that come from the hydraulic arm cylinder or the area around it is a very strong indication that mechanical damage is on its way and, therefore, the moment most often that this kind of damage is happening to the machine is nearing its eventual breakdown. These are the sounds coming from the processes that are wearing out the machine or those getting wrong within it.

- Banging or Knocking Sounds: Turning to loud, sharp noises, they are very frequently attributed to cavitation or aeration in the hydraulic fluid. Cavitation takes place when the pressure is reduced to such an extent that the space is occupied by vapor bubbles that suddenly collapse causing the internal damage that is accompanied by knocking-like sounds. At the same time, aeration induced by the air entering the fluid, causes a banging sound as the air compresses and decompresses. Both situations lead to rapid wear and seal failure.

- Hissing or Squealing Noises: A continuous hissing noise, which is usually more distinguishable during cylinder movement, normally indicates a significant external leak around the seals from where the high-pressure fluid is escaping. A very high-pitched squeal can, sometimes, be the result of excessive friction due to damaged or misaligned internal components, such as a bent rod that is binding against the gland.

- Vibration and Shaking: Overly strong vibration or shaking of the cylinder or the arm assembly while the machine is operating may be the component misalignment sign that includes the bent rods or the worn bearings in which the mounting points are, and that, consequently, the cylinder body and seals are getting too much and, therefore, these latter are at the risk of breaking.

If these sound alerts are rejected, internal damage is going on quickly and thus it will not take a long time before the parts that are wearing out very hard will break completely. So, using sound as a fast diagnostic tool can save you from a complete failure that costs a lot more if you have to replace your machinery without giving you a chance to intervene early.

4. Generating Too Much Heat

Hydraulic systems are less or more heat producers, in the case of normal operation, but still, the heat must not go beyond certain limits, which are usually less than $180^\circ\text{F}$ ($82^\circ\text{C}$). If a hydraulic arm cylinder is too hot or if the fluid temperature in the part of the circuit where the arm is located is very high, clearly there is a problem of significant internal friction or leakage.

- Unusual Cylinder Barrel Temperature: Excessive, local, and uncharacteristic temperature of the cylinder barrel is the indicator of severe friction or internal leakage. This is where fluid is escaping through a tiny gap past the piston seal, heating is caused by the forced fluid. The heat that is generated in this way further weakens the fluid as well as the seals, thus, the fluid’s viscosity gets lower and the rate of internal leakage gets higher very quickly – in fact it is a “vicious circle” of sorts.

- Seal Degradation Due to Heat: Extremely high temperatures, occurring during the cylinder’s operation, drastically shorten the life span of the elastomeric seals of the cylinder. The sealing elements can become hard and brittle, as well as crack and lose their original shape, which contributes to the occurrence of more leaks, further leading to increased heating and, finally, a complete cylinder breakdown.

- Fluid Viscosity Breakdown: The reason for hydraulic fluid’s viscosity going below the optimum level is excessively generated heat. Very thin fluid lubricates less and leaks internally more easily, additionally, the cylinder’s performance will deteriorate even further and a replacement will be needed sooner rather than later.

It is necessary to monitor and keep the temperature of the apparatus at the normal level if the life-span of the cylinder is to be long. If the issue of temperature still persists after the checking of the overall hydraulic cooler and reservoir levels, then the cylinder has to be the source of the problem because of internal wear.

5. Visible Damage of the Piston Rod or Barrel

The cylinder rod is the one that can be the most vulnerable to environmental damage and impact since it is the most exposed part of the hydraulic cylinder. The importance of the rod cannot be overemphasized since it is the smooth, hard-chromed surface that provides the sealing of the high-pressure fluid. Any kind of physical harm to the rod or the cylinder barrel will weaken the whole assembly.

Scoring, Nicks, or Pitting on the Rod: Deep scratches (scoring), dents (nicks), or rust/pitting on the surface of the piston rod are the signs that the failure of the cylinder is just around the corner and cannot be negotiated any further. These damages will quickly destroy the rod seals and gland, thus, external leaks will occur almost immediately and allow contaminants to enter.

- Bent or Misaligned Rod: The piston rod that looks bent to the eye or clearly functioning at an inappropriate angle to the barrel indicates side-loading (overloading) or the failure of the cylinder’s mounting points (the rod eye bushings, pins). Rod bending will make it causing binding, extreme friction, seal shredding, and, thus, an abrupt, sudden failure – in addition to it, the safety hazard greatly increases.

- Dents or Bulging on the Barrel: The presence of a dent or, which is worse, a slight bulge on the cylinder barrel, is a critical structural failure of the machine. A dent can prevent the smooth movement of the piston, whereas a bulge indicates that the inner barrel wall has been weakened by over-pressurization. In any case, the structural integrity is gone, therefore, the replacement is unavoidable for safety reasons.

It is always assumed that visible damage leads to immediate dismantling of the equipment with issuing a “stop work” order”. Besides, the damage that come into play while continuing to operate with a damaged cylinder rod is a high-risk gamble that will result in a much larger, more costly repair or a dangerous safety incident.

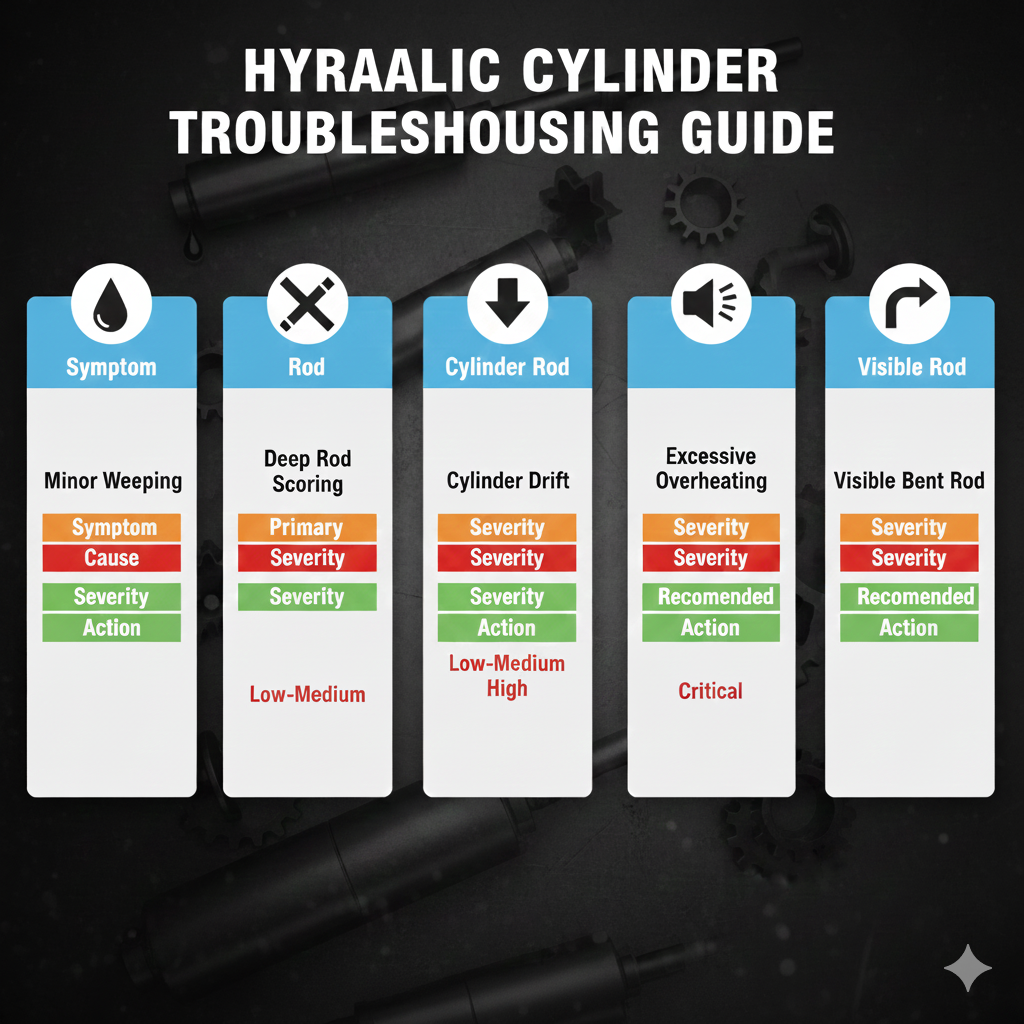

Tabular Format: Hydraulic Arm Cylinder Replacement vs. Repair

A simple seal kit may solve a problem with a minor external leak. However, most serious indications show internal and structural damage, therefore, a full replacement is needed. The table below is a guide for understanding the differences.

| Symptom | Primary Cause | Severity | Recommended Action |

| Minor Weeping/Dripping Leak | Worn rod seals/gland. | Low-Medium | Seal Replacement/Repack. |

| Deep Rod Scoring/Pitting | Contamination, impact, corrosion. | High | Cylinder Replacement (or Rod/Piston Replacement). |

| Cylinder Drift/Creep | Failed internal piston seals/scoring. | High | Cylinder Replacement or Rebuild (Rod/Piston/Barrel check). |

| Loud Knocking (Cavitation) | Internal damage, air contamination. | High | Full System Flush, Cylinder Replacement. |

| Visible Bent Rod/Barrel Damage | Overloading, impact, mounting failure. | Critical | Immediate Cylinder Replacement. |

| Excessive Overheating | Internal leakage, friction, fluid breakdown. | High | Cylinder Replacement (check system cooling). |

When the repair cost is almost as much as a replacement cost for a brand new high-quality welded rod replacement cylinder, which includes a new rod, seals, labor, and downtime, a full replacement from a trustworthy vendor is probably the most economical and reliable solution in the long run.

FAQs About Hydraulic Arm Cylinder Replacement

How long does an excavator hydraulic arm cylinder usually last?

There is no fixed time for replacing the hydraulic arm cylinder and, therefore, it is changed “based on its condition”. Its lifespan is mostly affected by the nature of the working environment, the frequency of maintenance, and the duty cycle. With strictly meticulously maintained, a cylinder can last over 10,000 hours of heavy-duty construction use. A replacement is the result of failure signs such as fluid leaks that are persistent, rod damage that is visible, or performance loss that is quite significant like drift or juddering, and not of a certain hour count.

- Condition-based replacement is much more affordable than calendar-based replacement.

- Heavy work at high speed and load will shorten the life of your cylinder very quickly.

- The biggest factor of lifespan is fluid quality – clean fluid will keep seals and surfaces safe.

What is the best course of action, repair or replacement, for a deeply scored piston hydraulic cylinder rod?

In the case of a deep scoring on a piston hydraulic rod, replacement is, in most cases, the safer and more cost-effective long-term option. A repair shop may be able to re-chrome or straighten the rod, but the cost and labor can amount to 60-80% of a new unit. A deeply scored rod is very likely to cause new seals to wear out quickly without much delay. Moreover, if a bent rod has been straightened, the structural integrity of it may be compromised, which is a huge safety concern, considering that the operation of the excavator involves high pressures.

What Is Cylinder Drift and Why Is It Dangerous?

Cylinder drift or creep means the unplanned movement of the arm cylinder (extension or retraction) when the control valve is in the neutral or “hold” position. The main reason of such a phenomenon is internal leakage (fluid bypassing the piston seal) or a holding valve that is faulty. The loss of positional control, which can further result in a dropped load, equipment collision or injuries of people working near the machine, is the danger that this phenomenon brings with it. It is an absolute indication of internal component wear that is severe.

Could I Arm Cylinder Be Damaged By Contaminated Hydraulic Fluid?

Definitely, yes. One of the major causes of premature hydraulic cylinder failure is fluid contamination, mainly from particulate matter (dirt, metal shavings) or water. Abrasive particles find their way between the seals and the piston rod or the cylinder bore, thus causing very fine scratches which are known as scoring. Later on, this scoring becomes the main agent which destroys the seals, thus leading to external leaks, reduction of the performance, and the ultimate need for replacement. Fluid testing and changing the filters regularly should be paramount.

What is “juddering” or “slip-stick” in a hydraulic cylinder?

Juddering is the intermittent, hesitant, or uneven movement of the hydraulic rod caused by the elastic release of energy due to high friction (the “stick” phase), which is immediately followed by the sudden, uncontrolled movement (the “slip” phase). The high friction is caused among others, by worn seals; thus, bind caused by a bent piston rod; or if the loss of lubrication is due to the degraded or contaminated hydraulic fluid. This is the indication of mechanical problems inside that need prompt inspection.

Does a Minor External Leak Mean I Have to Replace the Cylinder Immediately?

Not immediately in all cases, but the leak should be given urgent attention. Minor external leakage usually points to worn rod seals. If the piston rod surface is in a perfect condition and without any damage, a simple seal replacement (repack) may fix the problem. However, if there are scores on the rod or the leak continues after installing a new seal kit, the cylinder must be changed because the metal surface underneath is damaged and will continue to tear new seals.

What Can I Do to Prolong the Hydraulic Arm Cylinder?

Prevention is mainly through proper maintenance and good working habits:

- Keep the Fluid in Good Condition: Change filters and hydraulic fluid regularly as per the manufacturer’s instructions.

- Perform Routine Visual Checks: Inspect the piston rod daily for scoring, nicks, or corrosion before starting the work.

- Do Not Side-Load: Make sure the cylinder is not subjected to the force that is perpendicular to the rod as this will cause rapid wear of the seals and bearings.

Its Time for Hydraulic Arm Cylinder Replacement:

The hydraulic arm cylinder is a major investment and the heart of the excavator’s digging function for the heavy equipment operators and owners. Knowing the first signs of failure—the obvious leaks and rod damage as well as the subtle performance drops and noise—is instrumental in keeping the operational safety and in avoiding the financially devastating unscheduled downtime. When these serious signs are there, trust your judgment: oftentimes, the most reliable and cost-effective way is to replace the old, compromised cylinder with a high-quality, sturdy unit. Do not wait until full failure; regularly inspect, diagnose, and act ahead to keep your American Excavator in good shape.