Mini Excavator Ripper Attachment for: Breaking Hard Ground and Rock with No Sweat

Productivity is king in the ever-changing industries of construction, landscaping, and excavation, and the main gate to profit which can be doubled with Typhon Stomp Mini Excavator Ripper Attachment.

Each and everyone of a contractor’s soul most probably has experienced the hard ground, rock layers or frozen soil that with their craziness, easily put brakes on the progress. For these uncommonly high-resistance materials, the standard digging bucket is versatile but it has limitations that can cause wear to the machine and project time loss.

Prominence of Mini Excavator Ripper Attachment:

Mini Excavator Ripper Attachment is such a game changer in these scenarios. It was made to focus a whole machine’s hydraulic power onto one spot, and that’s precisely how a ripper, as a strong talon, effortlessly breaks the hardest material using its mighty power.

Moreover, for the smaller size equipment users, having Mini Excavator Ripper Attachment is less of a random upgrade and more of a well-thought-out decision (tactic) just one note away from a larger, more costly equipment (that can be bought).

American Excavator is about total understanding of the importance of the right tool for your success. When you, for example, are a winter builder getting a foundation ready, or a farmer clearing the land, then the ability to work efficiently in the ground very much determines the length of your project.

Having a Mini Excavator Ripper Attachment in your arsenal means that you are not only buying into better productivity and longer machine life but also the capacity of confidently taking on tougher work.

What is a Mini Excavator Ripper Attachment?

A Mini Excavator Ripper Attachment is a device especially made for penetrating compacted frozen soil, hard soil, rock, pavement, etc. It differs in operation from a bucket that splits the force over a broad cutting edge as it concentrates the entire breakout force of the excavator into a single heavy duty tooth or shank.

The intense force used by the attachment to crack materials that a bucket would no more than surface is due to the tehologies present in the structures that are made out of steel that is strong and resistant to wear. Normally the ripper unit is attached to the end of an excavator arm after removing the bucket and is secured using standard pins or a quick coupler system.

But the ripper’s design provides a natural ripping action as the excavator arm drags it through the ground resulting essentially from a simple lever action. Consequently, force application is made downwards and inwards, so that the material is pried apart rather than just being dragged on the surface.

For mini excavators, which have limited weight and hydraulic power compared to their full-sized counterparts, this efficiency is paramount. It allows a 3-ton machine to perform breaking tasks that might otherwise require a 5-ton or larger machine equipped with a standard bucket.

- Concentrated Power: Maximizes the penetration force by focusing the hydraulic power on a isolated point.

- Durable Construction: Produced from high-tensile steel for example AR400 to withstand deterioration and breakage.

- Versatile Design: Comes in different shank lengths and tooth styles for different ground conditions and machine sizes.

The Mechanics of Ripping: How It Works

It’s necessary to understand the working of a Mini Excavator Ripper Attachment so that you can use it in an optimized manner. It’s more than just the tooth being dragged through the dirt as a ripping technique is a method of strategically breaking the substrate into pieces.”

Firstly, the point of the sharp tooth comes out on the surface at the operator’s command of the ripping tool. The curved shank then behaves like a lever when the arm is being pulled back and the ground’s resistance to the shank thus allows it to act as a fulcrum lifting and fracturing the material along the fault line naturally.

The process being discussed here is far more environmentally friendly than that of striking or grinding because it exploits the material’s inherent weakness, namely tensile strength.

It is advisable to vary the depth of cut in accordance with the hardness level of the target material and the power of the mini excavator involved in the operation.

Veteran operators don’t think to use a ripper to tear the whole depth of a hole in a single run as the very deep ripping might stall the machine or put the hydraulic cylinders under excessive strain. On the contrary, they adopt a layering approach where a number of thin layers are gradually taken away until the ground is broken.

In addition to preserving the machine, this method leads to the formation of smaller pieces which not only facilitate the later cleanup but also American Excavator Ripper Attachment is such a processing tool that you will find that previously impenetrable terrain has been converted into loose material.

- Leveraged Principle: utilizes the machine’s geometry to pry and lift the material thereby breaking it efficiently.

- Layered Approach: the best application of the ripping tool is to remove layers of a tough material rather than doing deep penetration at once.

- Hydraulic Efficiency: unlike hammers, this tool needs less continuous hydraulic flow, thus it reduces fuel consumption and heat generation.

Key Applications: When to Use a Ripper

It is no exaggeration to say that the scope of a Mini Excavator Ripper Attachment is far-reaching in terms of the breaking of rocks.

Ripping frost removal is one the most identified usages of the tool. Frozen ground in places where the weather is cold is as hard as concrete. The ripper acts like a knife cutting through the layer of frost thus making it possible for excavation to continue even in the winter season which may even force other contractors to stop. This alone is a game changer as it increases your working time and thus your income for the year.

Moreover, root removal and land clearing is a major use of the tool besides ripping frozen ground. Roots of trees can not be easily cut with a shovel and besides that, it is them that are the cause of hydraulic shears break downs.

By hooking a claw under the main roots a ripper is able to tear them out of the ground without the use of a saw or an axe. This is very much the case in the forestry and the landscaping of residential areas where the maintenance of the surrounding soil structure is crucial.

Not only that rippers are great at demolishing old pavement or asphalt; chipped and broken pavement can very easily be removed by one big scoop after the slab has been pried and broken into pieces.

- Frost Breaking: Capable of penetrating frozen layers of soil thereby facilitating uninterrupted excavation work all year round.

- Root Extraction: Uses a hook to cling and tear apart the strong root systems without causing any damage to the main digging bucket.

- Pavement Demolition: The top layer of asphalt or the thin concrete slabs are lifted and broken for easy removal and disposal.

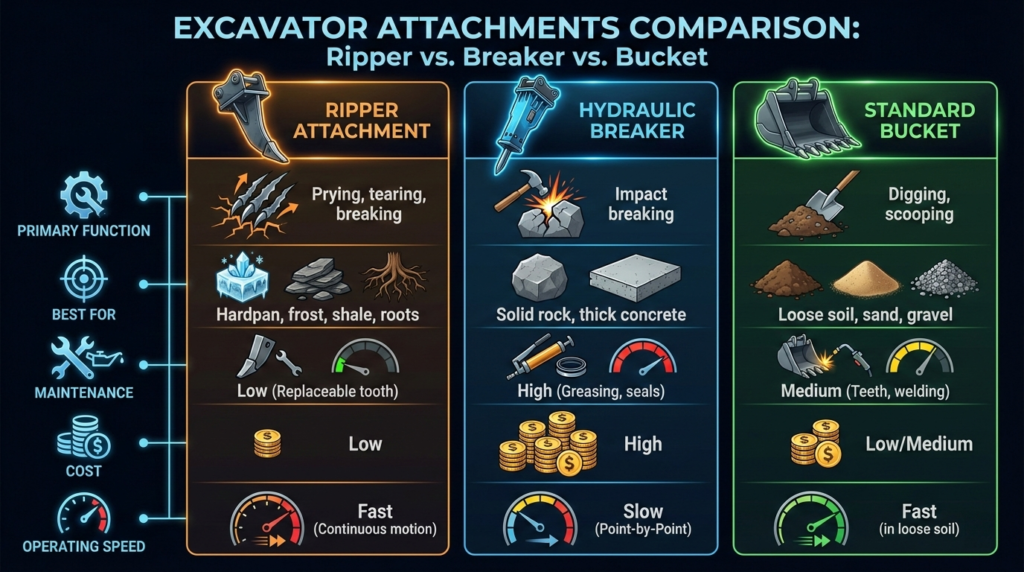

Comparison: Ripper vs. Hydraulic Breaker vs. Bucket

The first essential step towards cost control and saving time is picking a suitable tool. It may not be the best idea to use a hydraulic breaker (hammer) for solid bedrock or thick concrete, which is definitely the right tool for that case, but it is a terribly costly overshoot for hardpan soil, shale or frozen ground.

Breakers, due to their intricate moving parts and very high hydraulic requirements, are expensive not only in the initial purchase but also in the maintenance and operation. A Mini Excavator Ripper Attachment, eternal harmony, a cheap and beautiful, made with great simplicity,it hardly require anything more maintenance than replacing tooth.

On the contrary, employing a regular digging bucket for considerably tough ground is pretty much Running on Empty to your bucket is designed for scooping loose matter only. Getting a bucket into a rock or frost forcibly causes rapid wear of the teeth, the cutting edge and the welds used for the structural parts.

The boom and the pins of the excavator also get considerably stressed. A ripper, as the first step, breaks the soil thus your bucket is never a victim and hence you can go with a bucket for quick and easy removal of the ground at the time when the ripping is done already.

| Feature | Ripper Attachment | Hydraulic Breaker | Standard Bucket |

| Primary Function | Prying, tearing, breaking | Impact breaking | Digging, scooping |

| Best For | Hardpan, frost, shale, roots | Solid rock, thick concrete | Loose soil, sand, gravel |

| Maintenance | Low (Replaceable tooth) | High (Greasing, seals) | Medium (Teeth, welding) |

| Cost | Low | High | Low/Medium |

| Operating Speed | Fast (Continuous motion) | Slow (Point-by-point) | Fast (in loose soil) |

- Cost-Effectiveness: At the purchase and maintenance stages rippers are a lot more budget-friendly than hydraulic breakers.

- Machine Protection: Provides breaking up of soil before loading work, thereby, ensures bucket longevity and reduces structural stress on the excavator arm.

- Operational Speed: Unlike hammering, which involves a stop-and-go motion, ripping is continuous and allows for easy repositioning.

Choosing the Right Ripper for Your Mini Excavator

Basically, choosing a correct Mini Excavator Ripper Attachment centered on the idea of matching the weight and power of the machine to the specifications of the attachment. For instance, it cannot be a good idea that a huge ripper will be lifted by a small machine because of its heavyweight as such an unstable situation could bring about a downfall.

On the other hand, a tiny ripper might simply bend or snap as it will not be able to resist the breakout force due to the lack of strength.

One factor you can’t afford to overlook is the shank length. Power is needed to pull a shank that is longer through the ground but it also allows for deeper penetration. For mini excavators, a shorter, stouter shank is often preferred to maximize leverage and prevent stalling.

Besides, a Mini Excavator Ripper Attachment with a replaceable tooth is a wise choice as the tooth is the (element/component) most subjected to wear, plus easily changeable tooth that will also be sharp and effective long after this one has been used for a season.

- Weight Class Compatibility: To ensure safety and performance, always go for a ripper that is compatible with your specific excavator tonnage.

- Shank Geometry: Select the shank length that offers a good compromise between penetration depth and your machine’s breakout force.

- Replaceable Components: Go for standard easily sourced teeth and wear shrouds for long-term value.

Installation and Safety Protocols

Ensuring safety is the first and foremost thing that we do at American Excavator. The fitting of a Mini Excavator Ripper Attachment is a simple task, but it still requires the utmost caution to avoid any mishaps. Before commencing any work, make sure the excavator is on a flat surface, and the current attachment is lowered to the ground.

- Use gloves and goggles when manually driving pins if you happen to be utilizing a manual pin system since the metal chips can fly around.

- Check accordingly that O-rings and retaining clips are in place correctly to keep the pins from coming loose during operation.

Complete an inspection of the safety device after installation. Run through the attachment’s range of motion to the fullest to make sure the boom or cab aren’t obstructed by the attachment. In the operation of the machine, never pull the ripper to the cab place deeper than is necessary, and maintain awareness of the different utilities underground. If ripping in unknown terrain, always call 811 or your local utility marking service first.

- Secure Mounting: If we are talking about pins, clips and couplers, then the best practice is triple checking them for engagement and locking.

- Range of Motion Check: Slowly cycle the boom to verify clearance and ensure hydraulic hoses are not pinched (if applicable).

- Utility Awareness: Before ripping, check for underground hazards as rippers can go deeper than usual digging.

Why Choose American Excavator?

Opting for American Excavator means more than just purchasing equipment; it means partnering in your project success. Our promise of Unmatched Expertise is that we will assist you in understanding your options and finding the perfect Mini Excavator Ripper Attachment for your machine and application. Our Comprehensive Selection of top quality products tested for performance and durability under real-world conditions is to ensure that you have what you need when you want it.

Our Commitment to Safety

It is another aspect that differentiates us from our competitors. It is our prerogative to provide the means and the knowledge for each operator to use his/her equipment in a safe manner so that at the end of the day, both the crew and the machinery are there for the next opportunity to work.

Our Staff

Our Dedicated Support personnel are there to provide you prompt assistance whenever you need it most. Whether renting for a one-time job, or purchasing for a long-term fleet expansion, American Excavator is your reliable partner for earthmoving excellence.

- Expert Guidance: We match the attachment to your machine and project requirements with our expertise.

- Quality Assurance: We source only the highest-grade, durable attachments that can stand rigorous use.

- Safety First: We recognize operator safety as a priority and through education and proper equipment standards, we strive to maintain it.

Frequently Asked Questions – Mini Excavator Ripper Attachment

How do I choose the right excavator ripper attachment?

In order to select the best Mini Excavator Ripper Attachment to suit your needs, first, kind of, matching the attachment to your excavator’s weight class (e.g., 1-2 tons, 3-5 tons). Also, check the pin diameter and ear width to ensure it fits the coupler of your machine. Then, reviewing the type of material you will be working with, is in that case for extreme rock; then a ripper made out of high-abrasion steel like AR400 is the one to use.

Is it possible for a mini excavator ripper to break concrete?

Indeed, rippers can be used to smash asphalt and concrete slabs which are thin to medium. By hooking under the slab and using the lifting force of the excavator the concrete is snapped into pieces by the procedure. However, for very thick, reinforced concrete foundations, a hydraulic hammer (breaker) is generally more efficient and puts less strain on the machine.

What is the distinction between a single-shank and a multi-shank ripper?

A single-shank ripper channels all of the power of the machine into one point thereby, giving the highest penetration force to break very hard ground, frost, or rock. In contrast, a multi-shank ripper when combined the 2 or 3 teeth, spreads the force, so it is better for scarifying larger areas of moderately hard soil or loosening gravel, but less effective for breaking solid rock.

Can a mini excavator ripper reach very deep?

The depth is dependent on the length of the ripper shank and the layout of the excavator. Typically, the ripping depth of mini excavators is between 12 and 24 inches. Rather than trying to bury the shank altogether, which may end up stalling the machine, it is often more efficient to take off the layers in small increments (6-10 inches at a time).

What is meant by the maintenance of an excavator ripper?

Maintenance is simple but essential. The removable tooth’s state of wear and tear should be checked, and it should be replaced well before the shank begins to wear down. Look for any movement or damage to mounting pins and grease them if your setup needs it. Also, in the case of heavy rock work, inspect the shank and gussets welds for cracks.

Does a ripper outperform a bucket in terms of frost?

Yes, a bucket is not the best tool to break frozen ground, it will most probably skid over the surface or some teeth may be broken. The Mini Excavator Ripper Attachment can cross the frost layer and destroy it so that you are able to remove the frozen soil. It is the tool of choice for winter excavation in Western Canada.

Do I have to use a quick coupler with a ripper attachment?

It is not a must to have a quick coupler but it is very useful. After ripping the ground, you switch to the bucket to scoop the material. What will change your site efficiency enormously is being able to do the switch between the ripper and bucket in seconds by using quick coupler instead of manually driving pins in and out.