Fleet managers and heavy equipment owners are quite often faced with a scenario where they have to ask this question: “Should the maintenance of the fleet be predictive or preventative maintenance?”

Both measures have very typical features, and the correct answer will depend mostly on the size of your fleet, the way you operate, your budget, and what you want to achieve. Unlocking the power of excavators, skid steers, loaders, and other heavy-duty machinery can be a hard way, but when you hit the right maintenance strategy, it will work like a dream and be the only difference between flawless productivity and expensive downtime.

This blog is mainly about the differences between predictive maintenance vs. preventative maintenance where their benefits, challenges, and costs are unpacked. It also guides you to the right way as far as your fleet is concerned.

Understanding Preventative Maintenance

Preventative maintenance (PM) refers to a plan that is largely based on regular inspections, pre-paid service intervals, and recommendations by the manufacturers.

The concept is quite clear: deal with small issues before they develop into larger ones. This is proactive in nature but it does not rely on the data obtained in real time and rather goes by a fixed schedule.

- Routine Checks: Preventative maintenance is generally carried out through oil changes, lubrication, filter replacements and scheduled inspections at fixed intervals (e.g., every 250 or 500 hours).

- Manufacturer Guidelines: Most equipment manuals encourage preventative maintenance at certain usage milestones.

- Proactive Cost Control: Fleet managers are always intending to prolong the equipment life and thus prevent the occurrence of sudden breakdowns by effectuating these intervals.

Key Benefits of Preventative Maintenance

- Predictable Scheduling: It is easy to do so with maintenance because the scheduling will be done beforehand and thus the maintenance interrupting the flow of work is highly unlikely.

- Lower Upfront Investment: The only thing that is needed is a small amount of money for the routine maintenance and no sensors or AI-driven analytics are required.

- Extended Equipment Life: Equipment that is under regular check-up is less likely to be damaged via friction and hence less likely to require expensive parts change.

Common Challenges

- Over-Maintenance: Machines might be maintained more than maintenance necessity, thus leading to a waste of resources.

- Unplanned Breakdowns Still Occur: Some malfunction or issue can still go unnoticed even with scheduled check-ups, and result in breakdowns.

- Labour Intensive: It needs a dedicated staff for manual checks on service logs and to carry out frequent inspections.

Understanding Predictive Maintenance

Predictive maintenance (PdM) is a smart technology-based method that utilizes such devices as IoT sensors, telematics, and AI to gather data in real-time and to predict the time of failure of a component just before it happens. Predictive maintenance thus allows repair only at the time of failure and not prior to it as in the case of fixed schedules.

- Data-Driven Insights: The information about the machine’s functions such vibration, temperature, fluid levels, and pressure are being monitored by the sensors.

- Condition Monitoring: AI accompanied with software platforms interpret this data and identify the probable faults inside the system.

- Smart Scheduling: Through maintenance only the technically necessary hours, the problem during the stand-by period will be kept minimum.

Key Benefits of Predictive Maintenance

- Reduced Downtime: The diagnosis of problems is done prior to the occurrence of a failure resulting in downtime thus ensuring the availability of the fleet.

- Cost Efficiency: The repair will be targeted and done only if the part has been faulty thus saving the money that has been used for over-maintenance.

- Enhanced Safety: Apart from the operators and the crews who are the recipients of safety measures in this case, they too will be in a better position since they are less likely to experience sudden equipment failures.

Common Challenges

- High Initial Investment: This requires IoT sensors, telematics systems, and advanced analytics platforms all of which are costly initially.

- Skilled Workforce Required: Technicians are the persons who can handle the processes well but still they need to get prepared through training especially if the data is complex.

- Integration Issues: In case of the older fleets, the non-support of predictive technologies may create difficulties during the retrofit process.

Preventative vs. Predictive Maintenance: A Direct Comparison

One of the most effective ways to absolutely understand which of the approaches would be the most beneficial for your fleet is the side-by-side comparison:

| Factor | Preventative Maintenance | Predictive Maintenance |

| Approach | Time-based, scheduled servicing | Data-driven, condition-based servicing |

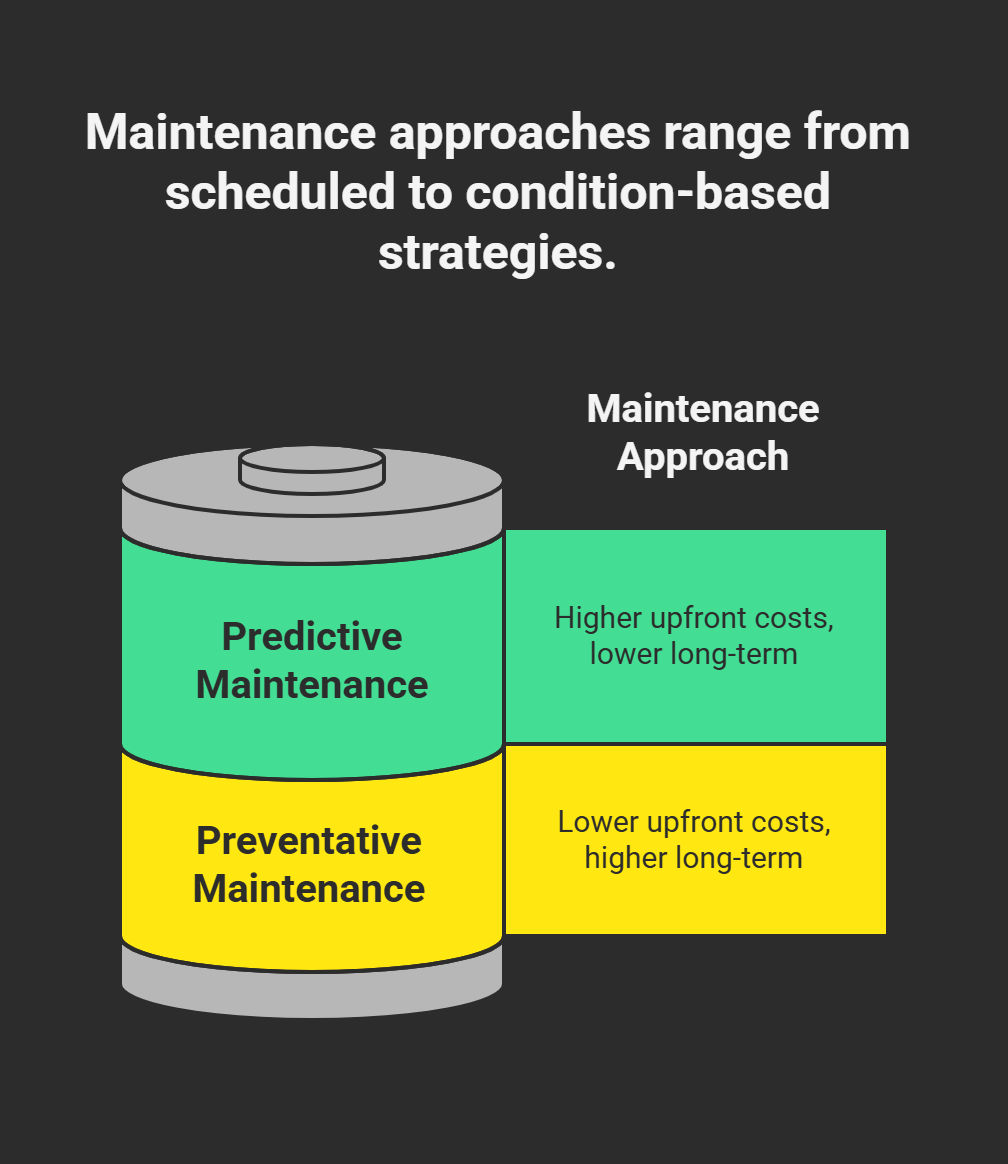

| Costs | Lower upfront, higher long-term (due to over-maintenance) | Higher upfront, lower long-term (due to efficiency) |

| Technology Required | Minimal (manual inspections, service logs) | High (sensors, AI, IoT, analytics) |

| Downtime | Possible, due to hidden failures | Minimal, as issues are detected in advance |

| Best for | Small to medium fleets, limited budgets | Large fleets, high-utilisation, long-term savings |

| Flexibility | Low — fixed intervals | High — based on equipment condition |

Which is Right for Your Fleet?

Deciding between predictive and preventative maintenance is contingent upon your fleet size, equipment usage, operating conditions, and budget constraints.

Preventative Maintenance is best when:

- You have a smaller fleet with a limited budget for advanced technology.

- Your equipment is running in stable conditions with a low possibility of sudden failures.

- You prefer fixed schedules and simple planning that does not depend on digital infrastructure.

Predictive Maintenance is best when:

- You manage a large fleet with high utilisation rates.

- Downtime leads directly to large financial losses.

- You are willing to invest in IoT sensors, telematics, and digital platforms for future benefits.

Cost Analysis: Preventative vs. Predictive

Let’s examine a real cost example of a fleet of 20 excavators:

| Cost Factor | Preventative Maintenance | Predictive Maintenance |

| Initial Investment | $0–$5,000 (basic tools, logs) | $50,000+ (sensors, software) |

| Annual Maintenance Cost | $80,000 (frequent checks, over-maintenance) | $60,000 (targeted repairs, reduced waste) |

| Downtime Cost Savings | Minimal | $100,000+ (fewer breakdowns) |

| ROI Timeline | Immediate, but flat savings | 2–3 years, exponential savings |

While preventative maintenance has lower initial costs, predictive maintenance provides greater long-term ROI for bigger fleets.

The Role of Telematics in Modern Fleet Maintenance

Telematics is the core of predictive maintenance. By connecting heavy machinery like excavators, bulldozers, and skid steers to centralised monitoring systems, fleet managers get real-time visibility into:

- Engine Metrics (RPM, temperature, fuel consumption).

- Hydraulic Pressure & Vibration Patterns to detect the wear minute part.

- Idle Time & Operator Behaviour to identify the sources of inefficiency.

The data does not only help the fuel manager optimize maintenance but also fuel efficiency, asset utilisation, and operator productivity.

Industry Trends in Fleet Maintenance

The heavy equipment industry is embracing digitisation at a rapid pace, with predictive maintenance:

- AI & Machine Learning: Fleets of vehicles that use AI and machine learning are now using predictive algorithms to analyze common traits and patterns found in different similar assets.

- IoT & Smart Sensors: Heavy machinery such as excavators and loaders are now equipped with monitoring systems as a standard feature through IoT and smart sensors.

- Remote Diagnostics: The use of cloud-based platforms has made it possible for technicians to carry out the process of equipment diagnosis from any location.

The predictive maintenance market is estimated by a 2024 MarketsandMarkets report to increase from $7.5 billion in 2021 to $23.5 billion by 2026, thereby confirming its swift acceptance in the industrial sector.

FAQs on Predictive vs. Preventative Maintenance

What Is The Main Difference Between Predictive And Preventative Maintenance?

Preventative maintenance is predominantly based on time, which means operations are carried out in planned intervals, whereas predictive maintenance is centered on the condition of the equipment where data and sensors are used to spot signs of failure at an early stage.

Is Predictive Maintenance Always Better Than Preventative?

Not exactly. The use of predictive maintenance is more efficient when it comes to saving money in the long run, but it is accompanied by a higher upfront investment. Moreover, smaller fleets may look at preventative maintenance as a better handier approach.

How Do Telematics Systems Help In Predictive Maintenance?

One of the main ways through which telematics can shed light on the health status of a machine in real-time is by monitoring various parameters such as engine data, vibrations, fuel usage, and operator behavior. As a result, the device can be replaced or repaired before the complete failure takes place.

Can Older Fleets Adopt Predictive Maintenance?

Yes that is true, but for older machines it might be necessary to install- retrofitted sensors and telematics devices. The cost of which can be high but often the benefits of reduced downtime justify the investment made.

Which maintenance strategy improves fleet uptime more?

Being proactive, predictive maintenance is the one which most of the time gives more fleet uptime as it lets the idea of breakdowns through the detection of issues before the process of the breakdown. On the other hand, preventive maintenance still carries the risk of unexpected downtime.

Is preventative maintenance outdated in today’s industry?

Not really. Preventive maintenance is still going strong especially in small fleets, rental companies, or businesses that have a limited budget for digital upgrades.

How do I decide which maintenance strategy is right for my fleet?

Take into consideration the size of your fleet, your budget, and your long-term goals. It is advisable that you choose predictive maintenance if your fleet is a large one and has a high rate of utilization. Preventive maintenance can still be used as a dependent method in the case of the smaller fleets.

The discussion about predictive vs. preventative maintenance does not refer to which one is the best universal – it is about what is the best for your fleet. Preventive maintenance gives off the aura of being less complicated and of having lower initial costs, thus being the most suitable for smaller operations. On the other hand, predictive maintenance, which is of data and telematics, can provide fleet maximum uptime and long-term ROI, thus being the best for large-scale fleets.

The above-mentioned are the considerations that a fleet managers and contractors in the construction, excavation, and heavy equipment industry, using preventative maintenance for smaller assets and predictive maintenance for high-value machinery might be a best approach hybrid model.

Even so, the trend goes toward technology and predictive maintenance is becoming the industry standard. However, preventative maintenance still has its place among those businesses that require a simple and less expensive solution.