Mini Excavator Attachments

The first and foremost thing that should be mentioned about the mini excavator is its ability to change the construction, landscaping, agriculture, and demolition industries with a wide range of attachments and its small footprint. However, it is the vast array of attachments that is the real key to unlocking their power.

This extensive manual delves the world of mini excavator attachments from the most common types and their applications to maintenance instructions and buying factors. Repacked with SEO technology “mini excavator attachments,” this article will help your projects and business make the right decision.

What Are Mini Excavator Attachments?

Mini excavator attachments are tools of specific kinds that could be installed on a mini-excavator to change its nature from a single-function machine to a multi-purpose one.

With a proper attachment, a mini excavator will do not only digging but also lifting, breaking, augering, grading, and even more, thus its output will be maximized at any site of work. The use of quick couplers and modern hydraulic systems not only makes the process of changing one attachment with another brief but also efficient.

Most Popular Mini Excavator Attachments

If you know what the right attachment will be for your work, then this will guarantee you to be cost-effective, safe, and have better results. Below you will find a list of the foremost in-demand mini excavator attachments with their key features:

1. Buckets

Buckets are the base of mini dimensions that represent one of the most important features of machine attachments.

- Standard Digging Buckets: Ideal for earthmoving and digging of a general nature.

- Trenching Buckets: Characterized by a narrow profile that allows the digging of trenches to be done accurately.

- V-shaped Buckets: The technologically advanced design allows it to be used in cutting and breaking of pavement and concrete.

- Grading/ Cleaning Buckets: Are used to level the ground and to clean hard-to-reach places especially around barrels.

- Rock Buckets: Are specifically designed with reinforced edges and skeleton body for handling and digging hard and compacted materials such as rocks, concrete, and so forth.

- Grading Buckets: Wider and less deep for leveling and backfilling works.

Main Advantages: Variety, as well as the effectiveness of the digging, the movement of material, and the cleaning of the site.

2. Hydraulic Breakers (Hammers)

Hydraulic breakers are the implements that are used to demolish the concrete, rocks, or asphalt.

Main Advantages: Powerful impact for breaking strong surfaces, lowering the need for human work, perfect for setting the site.

3. Augers

Mini excavators equipped with augers can drill holes with precision for fence post installation, planting, or footing construction.

Main Advantages: Drill with accuracy, save a lot of time when you have to make the same hole multiple times, and you can choose your size from different available ones for different tasks.

4. Thumbs

On the one hand, hydraulic thumbs and on the other – mechanical, in either case, they improve the gripping power of the mini-excavator when the object is of an irregular shape or is too large, hence, especially when buckets are present.

Main Advantages: Rock handling, wood handling, and management of debris and demolition materials are made easy with these accessories.

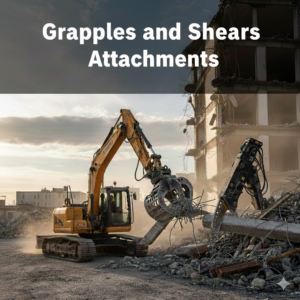

5. Grapples

Grapples allow the operators to grab a wide range of materials securely, then they can sort and move them (scrap, waste, timber, rocks).

Main Advantages: Resourceful material handling during cleaning of a site and demolition, also the safety, and the speed of the job are gotten improved.

6. Compactors

Compactor attachments work splendidly when there is a need to compress soil after an excavation or trench filling. Plate and roller types are the most frequent.

Main Advantages: They ensure that the foundations are strong, reduce future settling, as well as, increase the safety on the worksite.

7. Rippers

Ripper attachments are used to fracturing tough or compacted surfaces before digging.

Key Benefits: They can easily cut through even frozen soil, asphalt, or roots, hence such attachments are very useful for site preparation and land clearing.

8. Quick Couplers, Tiltrotators, and Powertilts

- Quick Couplers: It is possible to replace quickly and hence, one can work faster.

- Tiltrotators: They enable turning through 360° as well as tilting by up to 45° on each side for exact part placement.

- Powertilt: With this feature, the tilting function is added to the attachments thus the worker can easily reach tight or difficult spaces.

Key Benefits: These tools really help one to have more time, less fatigue and working flexibility that is not matched by any other means.

9. Mulchers

Mulcher attachments are used to cut down the growth of overgrown land rapidly which in return will allow the land to be used for other purposes in a short period of time.

Key Benefits: A tool which will help in landscaping, land clearing, and conservation work the most.

10. Clamshell Buckets, Orange Peel Grabs, Rotating Crushers

- Clamshell Buckets: These buckets are suitable for both deep digging and vertical material handling.

- Orange Peel Grabs: Mostly used together with scrap handling for moving large volumes of materials.

- Rotating Crushers: They do gradual demolition and break, crush and fragment the materials right there on the site.

Attachment Selection Guide

1. Assess Your Needs

- Task Type: Will the job involve digging, breaking, loading, grading, or clearing?

- Material: It can beoon,.type of soil, rock, concrete, debris, vegetation or any other materials.Frequency: Attachments you use daily may be of a higher quality or more specialized type.

2. Check Compatibility

- Size and Weight: Be sure that your excavator is able to handle the weight and the hydraulic pressure that the attachment requires in a safe manner.

- Mounting System: Only use such attachments which have compatible couplers and connectors.

3. Consider Quality and Brand Reputation

- Pick those brands which have a reputation for being reliable and which provide good customer service after the purchase.

- Look for the attachments that have a good number of positive reviews and come with strong warranties.

Maintenance Tips for Mini Excavator Attachments

- Inspect Attachments Regularly: Check for the signs of wear, cracks, and hydraulic leaks.

- Clean After Use: Helps to prevent rust and the accumulation of material.

- Lubricate Moving Parts: Make sure that the parts are working at their best and the life of the product is extended.

- Follow Manufacturer Guidelines: Carry out the recommended maintenance routines and use the suggested products.

Frequently Asked Questions (FAQ)

Q: Which mini excavator attachment is best for general usage?

A: The digging bucket of the traditional kind is the most versatile for most jobs, however, if you add a quick coupler, then you can double your flexibility.

Q: How do I know if an attachment will fit my mini excavator?

A: It is advised to confirm the working weight, hydraulic output and the coupling system of your machine. Have a look at the compatibility charts from your machine and the manufacturer of the attachment as well.

Q: Is it better to rent or buy attachments?

A: In case the task is repeated frequently, buying is more economical in the long run. However, for specialized work or if it is done only occasionally, then renting is a better option.

Q: Can I use regular-size excavator attachments on mini excavators?

A: No, attachments are the result of designing a specific size and weight, and the hydraulic segments of the excavator are the ones that match each class of the excavator. For safety and efficiency, always use attachments rated for “mini excavators”].

Conclusion

Mini excavator attachments are one of the main reasons for the drastic change in what one machine can do. Whether you are a contractor seeking for the right tools or a company adjusting to “mini excavator attachments”, getting familiar with the way of thinking about attachments, their characterization and best practices will be the your jobsites performance and investment’s value return. Go through your requirements, keep the focus on quality of the attachment.

Picking the suitable mini excavator attachments allows you to enjoy the outstanding versatility, increased efficiency, and a lower cost over time, which are thus vital for the toolkits of all the contractors.