Hydraulic Hammer vs. Mechanical Breaker: What’s Best for Your Excavator?

It is fair to say that heavy-duty construction work can depend a lot on what kind of attachment you choose to go with your excavator. A good choice can turn a project into a job done ahead of schedule while a bad one can be a major source of loss of efficiency and thus, of budget. One of the most contentious issues in the industry among these tools is Hydraulic Hammer vs. Mechanical Breaker. Both tools are aimed at disintegrating hard materials like rocks and concrete, however, their operating principles are quite different.

We at American Excavator believe that every machinery purchase is a kind of investment. Giving your excavator the best possible breaking tool is a good way of simultaneously getting more work done and lessening damage done to the carrier’s arm and hydraulic system. We can walk you through the working principles, pros, and suitable tasks of both hydraulic hammers and mechanical breakers in this detailed guide.

Understanding the Power Source: How Hydraulic Hammers Work

Hydraulic hammers or hydraulic breakers or “hoe rams” are extremely advanced attachments of an excavator that can draw the hydraulic power of the carrier to punch in a very powerful hit. The mechanism includes a hydraulic piston which frequently strikes the tool bit (usually a chisel or moil point) with the energy derived from pressurized hydraulic oil and, in many modern models, amplified by a nitrogen gas chamber that functions as an accumulator.

The greatest feature of a hydraulic hammer is its huge “blow energy,” which refers to the hammer stroke impact force expressed in foot-pounds or Joules. As it is part of the excavator’s hydraulic system, it can provide an extremely high impact rate of thousands of hits per minute, which is why it is absolutely the best choice for the toughest demolition and rock excavation jobs.

- Integrated Power: Connects to an excavator’s auxiliary hydraulic lines to generate a steady, high-frequency blowing action.

- Nitrogen Boost: Nitrogen gas is often utilized in the chamber to increase the impact force and also to reduce the shock transmitted to the excavator’s boom.

- Variable Speed: With the availability of adjustable blow frequency based on material hardness, the operator has total control over the procedure.

Simplicity and Strength: The Office of Mechanical Breakers

Unlike hydraulic breakers, mechanical breakers (other names for them are static breakers or ripper-style breakers) do not depend on the hydraulic flow of the excavator for generating an “impact” through a piston. Instead of this, they are able to break or rip the material by the mass of the excavator’s arm and the “crowd” force of the cylinders. A mechanical breaker can be thought of as an extremely hardened and reinforced point that replaces the bucket of an excavator.

They are not able to produce the fast landing of blows like hammers do, but they are recognized for their straightforwardness. There is no risk of leakage from seals, there is no requirement for nitrogen recharging, or complex internal valves. When it comes to breaking frozen ground, layered limestone, or secondary breaking where “prying” becomes just as crucial as “striking,” mechanical breakers offer a tough, low-maintenance choice.

- Low Maintenance: Mechanical breakers don’t have any internal components that move or wear out, so their maintenance costs are very low.

- Versatile Prying: The operator can pry apart slabs of concrete or rock instead of just pulverizing, which is a huge benefit for this kind of working method.

- Extreme Durability: These instruments have been built using high-strength reinforced steel capable of withstanding huge lateral forces that could snap the chisel of a hydraulic hammer.

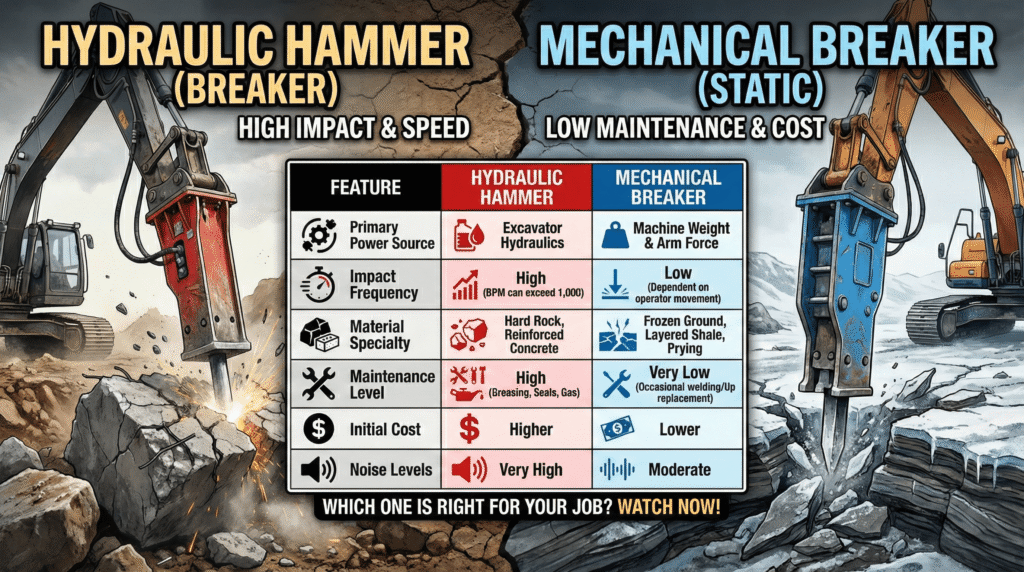

Performance Comparison: A Side-by-Side Analysis

Making a decision between Hydraulic Hammers vs. Mechanical Breakers means that one must know how the two perform in the real world. The table below shows the comparison of the key points such as performance, cost, and maintenance.

| Feature | Hydraulic Hammer (Breaker) | Mechanical Breaker (Static) |

| Primary Power Source | Excavator Hydraulics | Machine Weight & Arm Force |

| Impact Frequency | High (BPM can exceed 1,000) | Low (Dependent on operator movement) |

| Material Specialty | Hard Rock, Reinforced Concrete | Frozen Ground, Layered Shale, Prying |

| Maintenance Level | High (Greasing, Seals, Gas) | Very Low (Occasional welding/tip replacement) |

| Initial Cost | Higher | Lower |

| Noise Levels | Very High | Moderate |

Application Guide: When to Choose Which Tool?

The best tool choice is always dictated by the job that needs to be done. If you conduct the work that requires a mechanical breaker using a hydraulic hammer, you will most probably cause unnecessary fuel consumption and wear. On the other hand, you will most probably get no progress while wasting your time and effort if you try to apply a mechanical breaker to granite, a very hard rock.

Choose a Hydraulic Hammer when:

- You are demolishing reinforced concrete or rock to which no other solution can be applied.

- The on-site operating conditions are such that speed of work is of utmost importance.

- You need to break (excavate) soil vertically (for example in trenches or foundations for buildings).

Choose a Mechanical Breaker when:

- You are in a location where a hydraulic leak could cause environmental damage thus risk has to be minimized.

- The rock ‘layers’ in the material (shale and limestone, for example) can be separated by prying it open.

- Funds are limited and the amount of work at hand does not justify the expenses associated with a hydraulic system.

Maintenance Best Practices for Longevity – Hydraulic Hammer or Mechanical Breaker

Once you have made a selection of a tool, ample care should accompany it. No matter what tool you choose, hydraulic hammers with their complex technology require strictly controlled greasing procedures—with intervals not exceeding two hours of continuous work simply to prevent bushing deterioration.

On the other hand, mechanical breakers, despite their simplicity, also need the regular inspection of the “tip” or “point” and hard-facing welding which maintains their structural integrity.

- Greasing is Life: Always use a high-quality chisel paste for hydraulic hammers as it must be able to withstand extreme heat and pressure.

- Check Your Bushings: Keep an eye on the tool-to-bushing clearance; if there is an excessive gap, the internal piston might get damaged.

- Inspect for Stress Cracks: Mechanical breakers should be regularly checked for metal fatigue, particularly at the mounting pins and the “shank” area.

FAQ – Hydraulic Hammer vs. Mechanical Breaker

What is the main difference between a hydraulic hammer and a rock breaker?

In reality, both of these terms generally refer to the same thing – a tool that uses hydraulic power to deliver impact blows. However, technically, “hydraulic hammer” refers to the tool itself, whereas a “rock breaker” refers to the tool’s application breaking rock.

Can I use a hydraulic hammer on any excavator?

Not by a long shot. In order to correctly match a hammer to your excavator, apart from the weight, you also need to consider the hydraulic requirements (flow and pressure). If you use a hammer that is too big for your machine, it may tip over; whereas if it is too small, it will be inefficient and might cause damage to the carrier.

Are mechanical breakers better for the environment?

By and large, yes. Mechanical breakers have no hydraulic fluid inside them, hence the risk of a leak of contaminated oil on the construction site is zero. This is very important for working near water or in the protected areas.

How often should a hydraulic hammer be serviced?

It is advised to inspect the unit on a daily basis as well as to check the internal seals and nitrogen levels every 500 to 1,000 hours, of course dependent upon the type of work and the conditions.

Why is my hydraulic hammer losing power?

Some of the reasons may be such as nitrogen pressure in the accumulator being too low, the internal seals being worn, or a mismatch between the settings of your excavator’s hydraulic flow and those of the hammer. As a part of setting up your equipment, make sure that your “relief valve” is correctly set to the manufacturer’s specifications.

Is a mechanical breaker cheaper than a hydraulic one?

Yes. The difference can be seen in the initial cost as well as in running costs (including maintenance). Mechanical breakers possess a lower purchasing price and have a significantly lower “cost per hour” because they are without the costly internal components such pistons, valves, and diaphragms.

Which attachment is quieter for urban demolition?

Mechanical breakers make less noise due to the fact that they lack the repetitive “rat-a-tat” sound of a hydraulic piston as well as the “high-pitched whistles” of high-pressure pumping. Actually, if you own a hydraulic hammer, you can always use a “silent” or “box-type” housing that would mitigate the noise in residential areas.