Mini Excavator Ditch Bucket vs Standard Bucket: Which One Should Be Your Pick For Utility Jobs?

Optimization of work through the use of machinery requires that you invest in the right works tools in the same way you invest in the machinery itself. Operators and contractors in the field of utility work are usually faced with the choice of deciding which of the two main contenders will be the most suitable for the job: Mini Excavator Ditch Bucket vs Standard Bucket.

Indeed, a mini excavator is an extremely versatile and powerful tool for any work site, however, it only achieves its best if used with the most suitable bucket type. A standard bucket as a rule is the most common tool is built for power and aggression thus making it very suitable for breaking ground in the initial phases of your projects.

The ditch bucket on the other hand (also known as grading or cleanup bucket) is a tool designed for finesse, volume, and surface finishing.

Making the right choice between these two tool attachments could significantly help you avoid the risks of project delays and wastage of equipment besides enabling your utility installations to be as accurate as a surgical operation.

Seeing Through the Standard Bucket (The Digging Specialist)

A standard bucket or a digging bucket as it is sometimes called, is the staple attachment on virtually all mini excavators. It is typically fitted with tough, pointed teeth which are also replaceable, that are used to break into the hard soil, clay and even rocky ground with little effort.

It features a design that is greatly focused on delivering maximum breakout force by using the hydraulic power of the machine focused at the small though hard surface area of the teeth and using this force to break the hard ground. This bucket is the main tool of the utility workers particularly when it comes to digging trenches or other types of excavation for the first time.

It does not matter whether you are digging a cable trench for a short distance or if you are digging a sewer trench for a longer distance; the aggressive cutting edge of the standard bucket will give you the advantage of being able to get to the desired depths fast even when the soil is not in a good condition.

- Aggressive Penetration: The teeth are sharp and they can break through compacted dirt, roots, and even mild rock by concentrating the force.

- Narrow Profile: Normally, the width is less than that of ditch buckets, hence, the width of the trench can be precisely controlled so that the backfill material required is less.

- Structural Durability: Made of reinforced steel to resist the harshness of digging and leverage during excavating.

The ditch bucket (The Grading and Cleanup Pro)

The ditch bucket is located at the very different end of a spectrum from the standard bucket; it can also be called a grading, ditching, or cleanup bucket. Ditch buckets or grading buckets are mostly wide bucket attachments that don’t have pointed teeth (or any teeth at all).

Instead, they have a smooth, sharp edge that is perfect for trimming, leveling, and cleaning the surface. As opposed to being designed for breaking ground, buckets designed for ditches are used in washing or loading material. Utility workers, therefore, use ditches buckets to restore the site and prepare it.

After a utility pipe has been laid, the ditch bucket may be used to scoop the spoil pile and backfill the trench. Because of the smooth edges of the bucket, the operator can grade the surface and leave a flat, clean finish that requires hardly any manual labor.

If the utility project is in a residential area or a landscaped garden, the ditch bucket will be necessary for restoring the site to its original state without any damages left behind by the bucket’s teeth or uneven surfaces that the bucket has left.

- Smooth Cutting Edge: Teeth are replaced by a flat blade (which can be reversible) to get a smooth finish, and prevent damage to underground utilities during backfilling.

- High Volume Capacity: The wider configuration gives the bucket the ability to hold a lot more material; hence, the operation of backfilling and loading is sped up.

- Versatility in Finishing: The use of topsoil spreading, gravel leveling for pipe laying and cleaning of debris from work site, can be done very efficiently.

Key Differences: Design and Functionality

An analysis of Mini Excavator Ditch Bucket vs Standard Bucket shows that they have different design philosophies at their core. The standard bucket aims at penetration and depth, while the ditch bucket aims at width and surface area.

A standard bucket forces the earth exerting a high ground pressure in order to slice the earth; however, a ditch bucket lowers the ground pressure concentrating the force to level and make the material float.

With the teeth of a standard bucket you make “tracks” when dragging the bucket backward whereas the smooth edge of a ditch bucket acts like a squeegee smoothing the earth. Even more, the structural difference is evident: standard buckets have a curved back that helps them to curl and hold dense material whereas ditch buckets have flat bottoms that help them in leveling operations.

- Teeth vs. Blade: Standard buckets are equipped with teeth to increase the power of the digging; ditch buckets have a straight blade for exactness in grading.

- Width & Weight: Ditch buckets are typically wider but are usually made using lighter gauge steel in the non-wear areas that help maintain the bucket capacity without exceeding the tipping load of the machine.

- Soil Disturbance: Standard buckets leave a rough, toothed surface; ditch buckets leave a compacted, smooth surface ideal for sod or seeding.

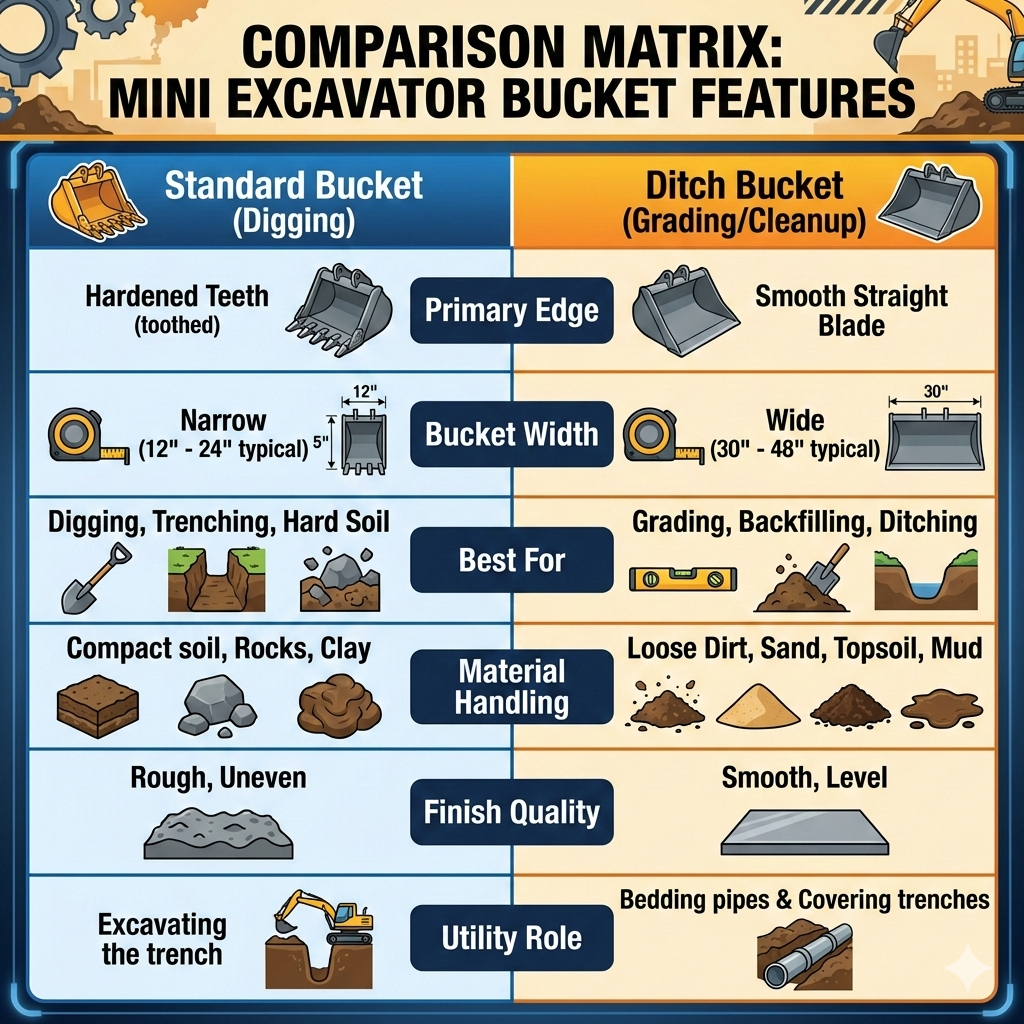

Comparison Matrix: Mini Excavator Bucket Features

| Feature | Standard Bucket (Digging) | Ditch Bucket (Grading/Cleanup) |

| Primary Edge | Hardened Teeth (toothed) | Smooth Straight Blade |

| Bucket Width | Narrow (12″ – 24″ typical) | Wide (30″ – 48″ typical) |

| Best For | Digging, Trenching, Hard Soil | Grading, Backfilling, Ditching |

| Material Handling | Compact soil, Rocks, Clay | Loose Dirt, Sand, Topsoil, Mud |

| Finish Quality | Rough, Uneven | Smooth, Level |

| Utility Role | Excavating the trench | Bedding pipes & Covering trenches |

Performance in Utility Jobs: The Verdict

When it comes to performance in utility jobs, the one that is considered the “winner” obviously depends on the various phases of the work. It is the standard bucket which is the champion when it comes to the opening of the trench during the process of the excavation phase.

A ditch bucket is simply not capable of digging hard packed ground efficiently; when trying to dig a deep trench with a ditch bucket a machine will be used to a great extent leading to low productivity. However, the standard bucket will be a disadvantage once the utility lines have been installed.

Risk of damage to pipes or cable jackets are present when backfilling using a toothed bucket unless the operator is extremely careful. Also filling trenches with a narrow bucket is very difficult and wastes a lot of time. Without a doubt, the ditch bucket comes out ahead most easily in this case. It is able to move more material per scoop plus it can finish smoothly within less time.

So, a fully utility job is considered to be done more effectively by using both the buckets i.e. a standard bucket to excavate and a ditch bucket to backfill.

- Excavation Phase: The Standard Bucket is the winner for speed and ability to reach the target depth of hard soil.

- Bedding Phase: The Ditch Bucket is the winner for easily placing sand or gravel bedding into the trench without disturbing the sub-base.

- Restoration Phase: The Ditch Bucket is a must-have for the final grading work and the leaving of a clean, professional job site.

When to Choose Which? Scenarios for Success

Sometimes an operator will only have one bucket on the site. The choice comes down to the main soil conditions and the level of precision required. If you have a utility job in a greenfield, characterized by the presence of hard clay and rocks, you need a standard bucket; you can slowly backfill with it but you cannot dig hard ground with a ditch bucket.

On the other hand, if your working environment is soft, sandy soil and you are carrying out maintenance of soft ditches i.e. muck removal, a ditch bucket might be good enough for excavations while giving you a superior finish.

On the other hand, professional utility contractors will not be arguing over “Mini Excavator Ditch Bucket vs Standard Bucket”. The point is that they are not in a polar opposite relationship but rather complementary partners that when quick coupled together lead to maximum efficiency and billable hours.”

- Choose Standard Bucket If: You are breaking fresh, hard ground, digging deep narrow trenches, or dealing with rocky substrates.

- Choose Ditch Bucket If: You are cleaning out existing wet ditches, backfilling large trenches, spreading gravel, or finishing a lawn after repair work.

- The Hybrid Approach: Some operators use a “thumb” attachment with a standard bucket to grab debris, effectively adding some “cleanup” utility to the digging bucket.

Maintenance and Durability Factors

Maintenance needs of the two items differ considerably. The standard bucket is a “high-wear” tool. The teeth are the parts that mostly suffer from the impacts and it is considered that they are consumables thus they need replacement from time to time.

If you let the teeth wear down to the extent that the bucket is damaged then you could be facing costly repairs. Ditch buckets unlike the standard bucket have a cutting edge that is a single and straight.

Over a period of time, this edge will wear out to the extent that it loses its ability to “cut” a clean grade. Most good-quality ditch buckets are fitted with a bolt-on reversible cutting edge which almost doubles the life of the blade.

And since ditch buckets are wider, the operator must be careful not to twist the boom when the corner of a wide bucket hits some immovable object. The twist force thus produced can also damage the arm of the mini excavator.

- Teeth Replacement: Standard buckets require regular inspection of teeth and retention pins to prevent loss during operation.

- Edge Maintenance: Ditch buckets require monitoring of the bolt-on edge; rotating it before it wears into the bucket shell is crucial.

- Structural Integrity: Ditch buckets have a larger surface area, making them more prone to denting if used to pry heavy boulders—a task best left to the standard bucket.

FAQs – Mini Excavator Ditch Bucket vs Standard Bucket

What is the difference between a ditching bucket and a digging bucket?

Basically, it’s the edge and the width. Digging bucket (Standard) is toothed and narrow, made to cut hard soil and to dig trenches. The ditching bucket (Grading) has a smooth, straight edge and is much wider, designed for backfilling and ditch cleaning.

Can I use a ditching bucket for digging?

You can dig with a ditching bucket only in soft, loose soil or mud. To dig with a ditching bucket in hard-packed clay or rocky terrain is very inefficient and it puts too much strain on the mini excavator’s hydraulics and boom, because of the high resistance of the wide, flat blade.

Which bucket is best for trenching utility lines?

The trench itself will be dug with the standard digging bucket since it can easily penetrate hard soil and it produces a narrow trench thereby minimizing the amount of earth you need to remove and replace. But for the backfilling phase of the job, the ditching bucket will be the better choice.

Do standard buckets come with teeth?

In fact, most of the standard digging buckets come with the teeth being the integral parts of the configuration. The teeth (sometimes called tips) are the tiny points where the machine’s breakout force ends up being concentrated for the ground to be fractured. Some light-duty standard buckets may have a smooth edge that can be bolted on but this is rarely the case for utility work.

How does bucket width affect mini excavator performance?

The size of the bucket effectively determines the weight of the load the bucket is going to carry. So, the wider the bucket (like a ditch bucket), the more material the bucket can hold which could make the machine unstable if the bucket is extended to its full capacity. That’s why it’s important to select a bucket size that corresponds to the weight class of the excavator to avoid tipping and to make sure that the hydraulic system of the machine can handle the lifting of the full load.

Is a grading bucket the same as a cleanup bucket?

Actually, the “grading bucket,” “ditching bucket,” and “cleanup bucket” terms are frequently used as synonyms in the industry. They are all referring to a wide bucket with a smooth edge that is meant for the final touch and for handling loose material.

Is a tilt ditching bucket worth the investment?

For work that involves uneven terrain or slopes, a tilt ditching bucket is highly popular and very useful. It allows the operator to tilt the bucket to the left or the right by up to 45 degrees making it possible for the operator to create drainage swales or to grade complicated slopes without having to move the tracks of the excavator.

Final Call To Make – Mini Excavator Ditch Bucket vs Standard Bucket

Mini Excavator Ditch Bucket vs Standard Bucket are actually complementary and not conflicting tools. The standard bucket is essential to forcefully dig trenches and break up hard ground making it the strongest member of the team.

The ditch bucket, however, scores with tidiness, speed of backfilling, and the ability to create a sleek finish that will please the client. Contractors who are successful in utility work understand that these buckets are teammates and not competitors.

By associating the standard bucket with the dig phase and the ditch bucket with the cover and clean-up phases, you guarantee efficiency, safety, and a top-notch deliverable that will stand the test of time.