Mastering Demolition Attachments: The Power of Excavator Grapples & Shears

In modern construction and demolition one of the main factors that differentiate a successful and profitable project from a costly delay is the kind of tools that are used at the end of the boom. Earthmoving would not be possible without the use of traditional buckets, but when the time comes to take apart reinforced concrete, to cut through structural steel or to unload and sort a ton of twisted debris, a special kind of power is needed such as grapples and shears excavator specially used for demolition attachments which works their magic in demolition sites.

The use of hydraulics in the devices represents the summit of the technology of the fluid transmission in general and converts what it was a simple machine into the precision instrument that cuts through the most fragile Surgical intervention. Contractors by how well they control these appliances, they can in fact significantly raise their production capacity, contribute to the safety in the workplace and make the most out of the recycling of the salvaged materials.

With the pace at which cities are being rebuilt, the need for precision demolition has reached an all-time high. The wrecking ball is out of fashion, and what we call demolition today is actually controlled deconstruction.

The question of which grapple or shear to use is what helps you ‘master’ the environment, regardless whether you are running a mini-excavator in a tight residential alley or handling a 50-ton monster on an industrial site. This manual unravels the working principles, the advantages, and the planned usage of these energetic tools to assist you in easing your work process and in having control over the rest of the team.

The Versatility of Mini Excavator

Among the different types of heavy machinery on a construction site, excavator grapples are the “hands”. A grapple, unlike a standard bucket that depends on gravity and scooping, offers a solid, mechanical hold on irregular-shaped items. The use of a grapple in activities ranging from clearing land of deeply rooted stumps to sorting mixed demolition waste into wood, metal, and concrete streams, makes it the most versatile specialist capable of handling a multitude of tasks simultaneously. Industry leaders’ hydraulic grapples, in particular, provide the feature of 360-degree rotation thus the operators are enabled to pick up the materials at the less conventional angles without the need of turning the whole excavator.

- Precision Sorting: The use of advanced grapples gives the freedom to the operators to handpick high-quality scrap metal out of the rubble pile, thus the return on investment of every demolition project is enhanced.

- Safety Enhancements: Grapples, by offering a firm, hydraulic hold, lessen the danger of falling debris hence the ground crews are kept safer and the chances of destruction to the property are lowered.

- Reduced Labor Costs: With the help of a rotating grapple, a single operator can perform the job that would take five-person ground crew, and that, in a small fraction of the time, especially when it comes to site cleanup.

Engineering Force: How to Master Grapples and Shears Attachments?

Excavator shears are the best option when the required task is to work on structural steel, rebar, or heavy-duty pipes. The main method the tool uses is the application of massive hydraulic cylinders to produce the pressure of a few thousands of tons at the “throat” of the blades, which results in the “shearing” of metal close to the way scissors do with paper. This excludes the use of slow manual torch-cutting method that is not only time-consuming but also has significant fire hazards and toxic fumes. The shears have been made in a way that the parts that have been replaced due to wear ensure the tool remains sharp and efficient even after long-term processing of abrasive steel.

- High Cutting Force: Demolition shears specially made can single-handedly cut steel beams and reinforced concrete columns, thus dismantling can be done much faster.

- Cold Cutting Safety: Using shears removes the need for an open flame on-site, which is very important in industrial environments or projects where lead-painted steel is involved.

- Material Processing: The “downsizing” of scrap metal by shears is the first step to on-site material ready for integration in transport trailers, which contributes greatly to the logistics intention of cost reduction.

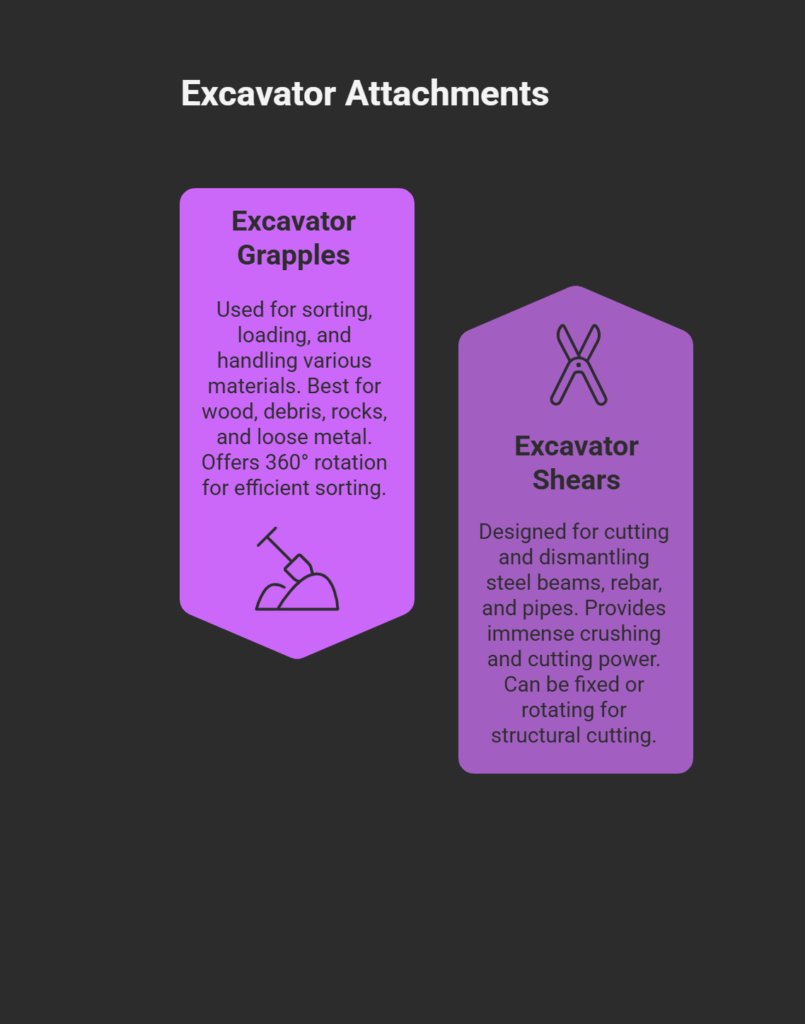

Comparing Grapples and Shears: A Strategic Overview

Although both attachments are t The comparison below will assist you in making the decision which tool fits the stage of your demolition work best.

| Feature | Excavator Grapples | Excavator Shears |

| Primary Function | Sorting, Loading, and Handling | Cutting and Dismantling |

| Best For | Wood, Debris, Rocks, and Loose Metal | Steel Beams, Rebar, and Pipes |

| Movement | Often 360° Rotation for Sorting | Fixed or Rotating for Structural Cutting |

| Material Type | Irregular and Bulky Materials | High-Density Metal and Concrete |

| Key Advantage | Extreme Versatility and Speed | Immense Crushing and Cutting Power |

Hydraulic vs. Mechanical: Selecting the Right Power Source

When searching for excavator attachments, the decision between a hydraulic and a mechanical feature will often have to be made. Mechanical grapples (also known as “stiff arms”) are a cheaper option and operate by the bucket cylinder’s movement against a fixed arm. Yet, the hydraulic ones are considered as the best choice when it comes to “Mastering Demolition”. The use of hydraulic grapples and shears gives them the freedom of movement, thus much more significant range and much higher clamping forces are possible.

- Superior Control: Hydraulic systems enable “feathering” the controls, which is essential when work is carried out in proximity to standing structures or underground utilities.

- Consistent Pressure: In contrast to mechanical versions, hydraulic attachments can still perform at their maximum gripping or cutting force even when the boom is in a certain position.

- Durability: The modern hydraulic attachments are made from high-tensile, wear-resistant steel (like Hardox), and are thus very capable of handling 24/7 demolition cycles without breaking down.

Enhancing ROI Through Demolition

Demolition has evolved beyond “breaking things”; it is now about resource recovery. The leading equipment for site sustainability are the excavator grapples and shears. By the use of a shear, the rebar can be separated from the concrete in a clean way, or by the use of a grapple, the timber can be separated from the masonry, thus

- Clean Scrap Streams: When a grapple is used to sort materials at the point where they are obtained, cross-contamination is prevented, thus you get the highest price for salvaged metal.

- Concrete Recycling: The shears can be used to assist reinforced concrete in the process of pulverization, thus making the process of turning old foundations into recycled aggregate easier.

- Logistics Optimization: when materials are processed on-site and are transformed into manageable sizes, it results in the need for fewer truck trips and thus the lower consumption of fuel.

Maintenance Tips for Longevity in Excavators

The typical demolition scene is a very harsh one. Demolition sites are places where dust, metal shards, and high-impact vibrations are abundant and they can be very detrimental to your attachments that are mounted on the excavators.

To keep the “power” of the shears and the grapples, a thorough maintenance regimen is absolutely necessary. Apart from preventing unexpected downtimes, this also guarantees that your machines will maintain their resale value throughout the years.

- Daily Lubrication: The areas of the machine that are under heavy friction such as the pivot points and cylinder pins should be greased daily in order to prevent premature wear and “pin-slop”.

- Blade Rotation: The majority of the modern shears come with indexable blades; by rotating them regularly you will not only have a sharp cutting edge but you will also prevent the strain on the cylinder.

- Hydraulic Inspections: Be on the lookout every morning for leaking seals or worn-out hoses. Even a tiny leak in a high-pressure system can be the reason for a major failure that can occur when the system is under heavy load.

FAQs: Master Demolition – Grapples and Shears Attachments

What is the difference between a demolition grapple and a forest grapple?

A demolition grapple is constructed out of heavy-duty, wear-resistant steel and usually has “box-style” tines or perforated shells for dealing with abrasive rubble and metal. A forestry grapple is generally lighter and its curved tines are specifically designed to go over the soil while gripping logs or brush. If you use a forestry grapple for demolition, it can cause the bending of the tines and eventual structural failure of the grapple.

Can I use an excavator shear to cut concrete?

As far as “multi-processors” are concerned, only few of them can handle both but a dedicated steel shear is a metal cutting one. The blades of the steel shear will be chipped if it is used on heavy concrete. For projects that have a lot of concrete, the use of a “cracker” or “pulverizer” is the best option, though some contractors use “combi-shears” that have a concrete-crushing throat and metal-cutting blades at the back.

How do I choose the right size grapple for my excavator?

The grapple should be suitable for the operating weight and hydraulic flow of your machine. A heavy grapple will make the excavator unstable and will put a strain on the hydraulic system, while a small one will not be able to make full use of the machine’s power. It is always a good idea to check the manufacturer’s “Carrier Weight” specifications before you make a purchase.

Are rotating grapples worth the extra cost?

Certainly. 360-degree rotation in demolition and sorting work gives the freedom to the operator to pick up material from any angle without the need of moving the tracks. As a result of this, fuel consumption is lowered, the undercarriage is less worn out, and at the same time, the loading of trucks in confined spaces becomes much faster which allows more work to be done in the same period of time.

How often do shear blades need to be replaced?

It depends on the type of the material that is being processed. If the cutting is made on “clean” structural steel the blades can be used for several hundred hours. When the material is “dirty” scrap with sand or concrete on it, the wear will be faster. Most of the operators will rotate or “flip” the blades every 80–100 hours so that they can maintain their peak performance.

Do I need a third hydraulic circuit for a grapple?

If you have a basic mechanical or “stiff-arm” grapple, then the answer is no. Nevertheless, for a rotating hydraulic grapple, you normally require “auxiliary” hydraulic lines (sometimes referred to as 3rd and 4th function) that can provide power to opening/closing as well as the 360-degree rotation motor.

Is it better to rent or buy demolition attachments?

The answer is buying, in most cases, especially if you have a project that will last for more than three months and the great part of the return on investment will come out after these three months, also taking into consideration the high resale value of quality attachments. Renting, on the other hand, is good for one-off specialized jobs as it gives you an opportunity to use the latest technology without investing the capital.