Top Advantages of Working with a Hydraulic Break Hammer on Mini Diggers & Crawlers

If you are planning to do construction or demolition work in the near future, carefully selecting the right equipment for your work can both significantly speed up your timelines and save you plenty of money. For contractors and site managers who want to get the most out of their time and efforts, the addition of a hydraulic break hammer to mini diggers & crawlers is pretty much an unbeatable solution.

These highly efficient attachments not only save you the cost of heavy machinery by giving mini excavators the power of full-sized demolition machines but also widen the range of uses by adding the ability to break tough materials such as reinforced concrete or hard rock layers.

With the reuse of the excavator’s hydraulics to power the hammer, it’s no longer necessary to carry heavy air compressors and pneumatic tools around, so the site becomes messier-free and the costs of operation are much lower. This write-up is a comprehensive review of the major reasons why combination power mini-diggers hydraulic break hammers with crawlers have become industry standards.

Unparalleled Versatility in All kinds of Operations

If you choose to pair a hydraulic break hammer with mini diggers & crawlers, you are essentially purchasing the key tool for changing the utility of the fleet.

A mini excavator outfitted with a hydraulic breaker isn’t a one-trick pony that merely tear down old driveways, that can also get in-depth utility trenches, or be useful in quick demolition of structures in odd spaces.

Essentially, the hydraulic hammer turns the operator of the small machine into a super-human capable of performing demolition and construction work that would normally have been meant for heavy equipment. In effect, it prolongs your machinery life and justifies your investment.

- Multi-Material Capability: Cracks cement, asphalt, limestone, and even frozen ground without difficulty, making it a versatile tool throughout the year.

- Task Flexibility: Perfect for a variety of tasks such as trenching, foundation removal, landscaping, and road repair.

- Interchangeable Tooling: Most hydraulic breakers are available with different tool bits (moils, chisels, blunts) to maximize the efficiency of the breaker for the material being broken.

Unheard Level of Accuracy and Control While Working in Built-up Areas

When the location dictates that the demolition has to be done near other existing buildings or underground utilities that you really have to be careful to not damage, then precision is the key.

In a hydraulic break hammer with mini diggers & crawlers, you are crystal clear on the task since the breaker is under the boom and arm of the excavator and the operation is done near the comfort of the cab. It is a scenario where you pick the part of the house you want to tear down and leave the rest intact.

Another thing is that mini-diggers are compact and therefore have the most suitable morphology for work in narrow backyards, inside buildings or narrow alleys where it is impossible for bigger machines to get through. Knowing that you can be precise with the hydraulic nature of the breaker, you have no doubt that neither the neighbors’ homes nor the roads will be harmed.

You probably will also be able to limit as well as lower the costs of the manual labor required to clean up the site after work because the hydraulic breaker will be so gentle and accurate.

- Spot Demolition: Capable of removing targeted sections of concrete or rock with minimum disturbance to the surrounding areas.

- Confined Space Access: Mini diggers are able to come through standard gates and doorways and extend hydraulic power to remote areas.

- Vibration Management: The latest breakers are engineered to concentrate the force on the material rather than on the carrier, thus ensuring the safety of the nearby sensitive structures.

Major Savings and High Return on Investment

Essentially, everything comes down to the bottom line for construction businesses and it is safe to say that adopting a hydraulic break hammer with mini diggers & crawlers is one way to give your bottom line a huge boost through high ROI.

Components powered by a hydraulic breaker are broken at speeds that overwhelm manual methods significantly in terms of speed. A hydraulic breaker with a single operator can demolish what a crew of workers with handheld pneumatic tools might break over a period of several days.

Apart from the huge reduction in labor-intensity, this also results in dramatic savings on the labor costs. Moreover, because the hydraulic breaker is powered from the excavator’s system, there is also no need to bring in an additional air compressor and diesel engine. This step alone significantly reduces maintenance, contractor fuel, and operator costs.

Attachments like this are known to have a very long lifecycle, which only adds to the value of each project.

- Labor Savings: Takes the place of human effort of several workers, and lets you repurpose the labor to other vital tasks.

- Reduced Equipment Rental: Avoids the need for separate compressors and jackhammers, thus, simplifying your equipment needs.

- Faster Project Completion: Speeds up project timelines because of rapid demolition and thus, you get more jobs done in the same period of time.

Heightened Operator Safety Measures

Moving from the standard demolition methods to working with a hydraulic break hammer with mini diggers & crawlers greatly lessens the chances of site accidents. Even though a manual demolition with handheld jackhammers comes with noise and health hazards such as silica dust and Hand-Arm Vibration Syndrome (HAVS), just to name a few, workers are not physically exposed when the operator is inside the cab of the mini excavator.

Furthermore, the cab shields the operator not only from visible dust and noise but also from the physical impact of the flying debris. Not only does working with a breaker in a cab reduce the risk of chronic diseases to exposure to vibrations and dust but also the risk of musculoskeletal disorders caused by carrying heavy tools is eliminated.

Additionally, it removes the risk of accidents due to worker fatigue and has a positive impact on productivity.

- Elimination of HAVS Risk: Operators only need to use joysticks to control the breaker, and therefore, do not come in contact with the vibrating tool.

- Debris Protection: Most excavator cabs (especially those that are equipped with ROPS/FOPS) serve as great shielding against concrete shards and other debris.

- Dust Distance: Since the point of impact is a few meters away from the operator’s position, it limits their exposure to freshly generated dust and other particulates.

Resilience and Technological Innovations

Hydraulic breakers today are simply amazing pieces of mechanical engineering that are not only built to last but also very efficient. Once paired with a reliable hydraulic break hammer with mini diggers & crawlers, it will be hard for you to find a piece of machinery that does not trim its energy consumption but at the same time increases its performance.

One feature that is rapidly getting popular among the newer models is the “blank firing protection,” which is designed to prevent the hammer from cycling if it is not pressed firmly against the surface thus preventing damage to the piston and cylinder. Other features, such as auto-lubrication systems, help keep the breaker from overheating during operation and help the breaker parts last longer.

Thanks to the use of heat-treated, high-quality steel alloys, the comprising parts of the breaker are now very sturdy and can therefore last longer even with consistent and heavy usage.

- Blank Firing Protection: An internal mechanism identifies the lack of load and stops the piston from striking thus avoiding severe damage to the parts.

- Auto-Lubrication: These systems either standard and/or optional provide continuous greasing application thus, reduction of downtime and extension of tool life.

- Noise Reduction Technology: The enclosed structure designs greatly muffle noise levels thereby, making them comply with tough urban noise standards.

Best match breaker size for mini excavators

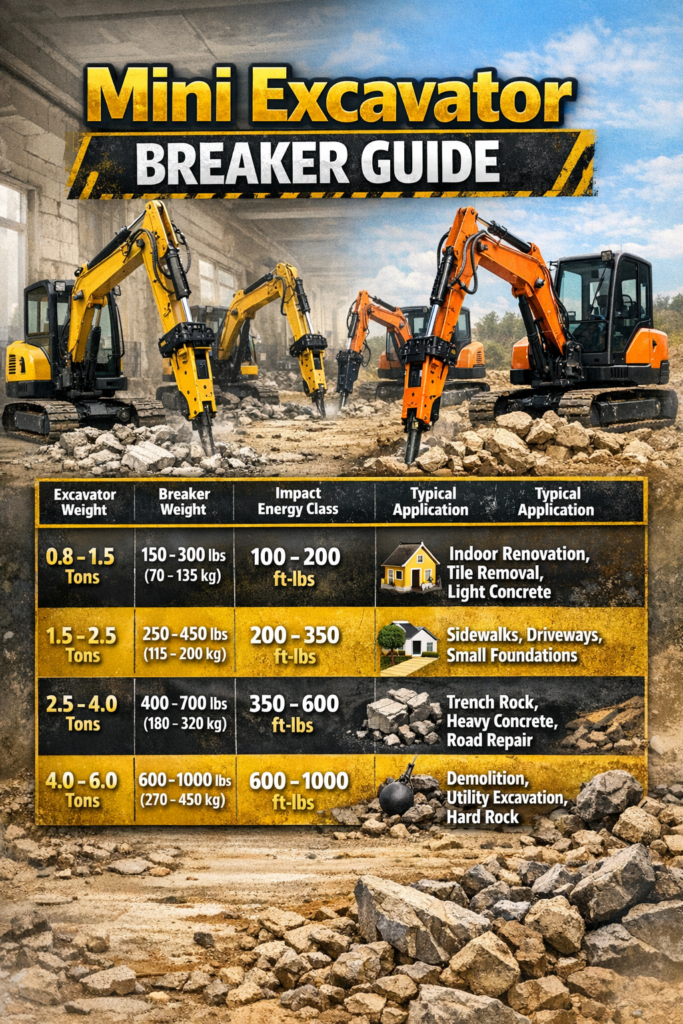

To be able to enjoy all the “Top Benefits” discussed above, the first thing you must do is to properly size your hydraulic breaker to match both the mini excavator and the job in hand. This is because if the breaker you choose is too big, it will damage the excavator’s boom and hydraulic pump while if your breaker is too small, it won’t have the impact energy it needs to get the job done.

The below table is a rough guide for matching breaker weight to excavator class and therefore, ensuring performance and safety are at the optimum level.

| Mini Excavator Weight (Tons) | Recommended Breaker Weight (lbs/kg) | Impact Energy Class (ft-lbs) | Typical Application |

| 0.8 – 1.5 Tons | 150 – 300 lbs (70 – 135 kg) | 100 – 200 | Indoor renovation, tile removal, light concrete. |

| 1.5 – 2.5 Tons | 250 – 450 lbs (115 – 200 kg) | 200 – 350 | Sidewalks, driveways, small foundations. |

| 2.5 – 4.0 Tons | 400 – 700 lbs (180 – 320 kg) | 350 – 600 | Trench rock, heavy concrete, road repair. |

| 4.0 – 6.0 Tons | 600 – 1000 lbs (270 – 450 kg) | 600 – 1000 | Demolition, utility excavation, hard rock. |

FAQs Hydraulic Break Hammer with Mini Diggers & Crawlers

How do I choose the right hydraulic breaker for my mini excavator?

You can only select a hydraulic breaker that’s suitable for your mini excavator if you first know the weight of the excavator and the flow of the auxiliary hydraulic. The flow rate is usually given in gallons or liters per minute. To determine these specifications, one can refer to the mini excavator’s manual under “operating weight” and “auxiliary hydraulic flow.”

Once you have the measurements of your machine, you can select a breaker that is within these ranges. If the flow of the breaker is more than what your machine can supply, then the breaker’s performance will be poor. On the other hand, if the breaker is too heavy, it can lead to stability issues and damage the boom of the excavator.

What is the difference between gas-fired and fully hydraulic breakers?

Gas-fired (or nitrogen-assisted) breakers use a chamber of compressed nitrogen gas to provide a significant portion of the impact energy. They generally pack more punch per pound, feature less moving parts, and as a result, tend to be more reliable; however, they will need the nitrogen to be refilled regularly.

Fully hydraulic breakers primarily use the excavator’s hydraulic oil flow for power. They generally provide steady impact energy regardless of hydraulic supply variations and tend to be quieter but can have more complicated internal mechanisms. Both models perform well in general, though gas-fired units seem to be better suited for hard rock applications.

How often should I grease my hydraulic hammer?

Greasing your hydraulic break hammer periodically is very important for the lifespan of the tool. You should grease your hammer manually every 2 hours of non-stop work time at least. If you are working in very dusty or abrasive conditions, or if the hammer is positioned horizontally, then you might have to grease even more frequently.

It is always advisable to use the chisel paste of high temperature that is recommended by the manufacturer as normal chassis grease melts and runs out, thus leading to rapid bushing and tool wear.

Can I use a hydraulic breaker on a mini excavator for concrete demolition?

Definitely so. Hydraulic breaker attached mini excavators are a perfect match not only for concrete demolition but also for the breaking up of any hard surfaces like driveways, sidewalks, patio slabs, and building foundations. The secret weapon is the correct use of tool bits.

You see, normally a chisel or wedge point is best suited for concrete work as it allows the force to penetrate and split the material. When you start from the edge and work your way inward, the chisel will keep the force from being stuck in the concrete.

What maintenance does a hydraulic breaker require?

Besides the frequent greasing, breaker maintenance should include checking the hydraulic hoses for wear or leakage on a daily basis, inspecting the tool bit (chisel) for cracks or excessive wear, and checking the tension of the side bolts and other fasteners.

You should also check nitrogen gas pressure (if your model uses this) and the wear bushings periodically. Furthermore, you need to keep the hydraulic oil clean in order to prevent the oil from contamination which can quickly damage the precision internal components of the breaker.

Why is my hydraulic breaker not striking?

There could be various reasons why the breaker is not striking, with a few most likely ones listed below:

- Low Hydraulic Oil/Pressure: Ensure that your excavator has enough hydraulic fluid.

- Closed Valves: Make sure the auxiliary hydraulic lines are open and that flow is directed to the attachment.

- Internal Damage: Broken piston or seized valve.

- Gas Pressure: Twisting of nitrogen could be either too low or too high.

- Insufficient Down Pressure: The Operator may need to be applying more pressure to the mechanism so that it engages.

Is it better to rent or buy a hydraulic breaker?

This really depends on how often you will use the breaker. If most of your jobs (over 40-50%) require a breaker, then purchasing one might be more economical with better ROI in the long run. In case you only need a breaker for a one-off project or occasional use, it is more practical to rent from a reliable company such as American Excavator.

Renting helps you to avoid storage and high maintenance costs and also makes sure that you always have access to modern and well-maintained equipment suitable for your specific task.

In summary – Choose the Best Hydraulic Break Hammer on Mini Diggers & Crawlers

A hydraulic break hammer fitted with mini diggers & crawlers is a winning formula that significantly increases the performance, safety, and profitability of your construction business.

The main points you should remember are the flexibility of this equipment which allows you to carry out a variety of tasks, the high precision that makes it suitable for urban work sites, and the fact that the benefit-to-cost ratio is so high that the device pays for itself many times over. With the proper care and using the right instruments at the right time, you are guaranteed timely and budget-friendly completion of projects.

We at American Excavator live our mission of providing our customers with relevant industry insights and practical equipment solutions on a day-to-day basis. We are capable of fulfilling your rental needs or helping you invest in your fleet attachments, and either way, understanding these top benefits will be a step forward for your business.