The Future of Digging: 5 Ways Autonomous Machinery is Changing Earthmoving

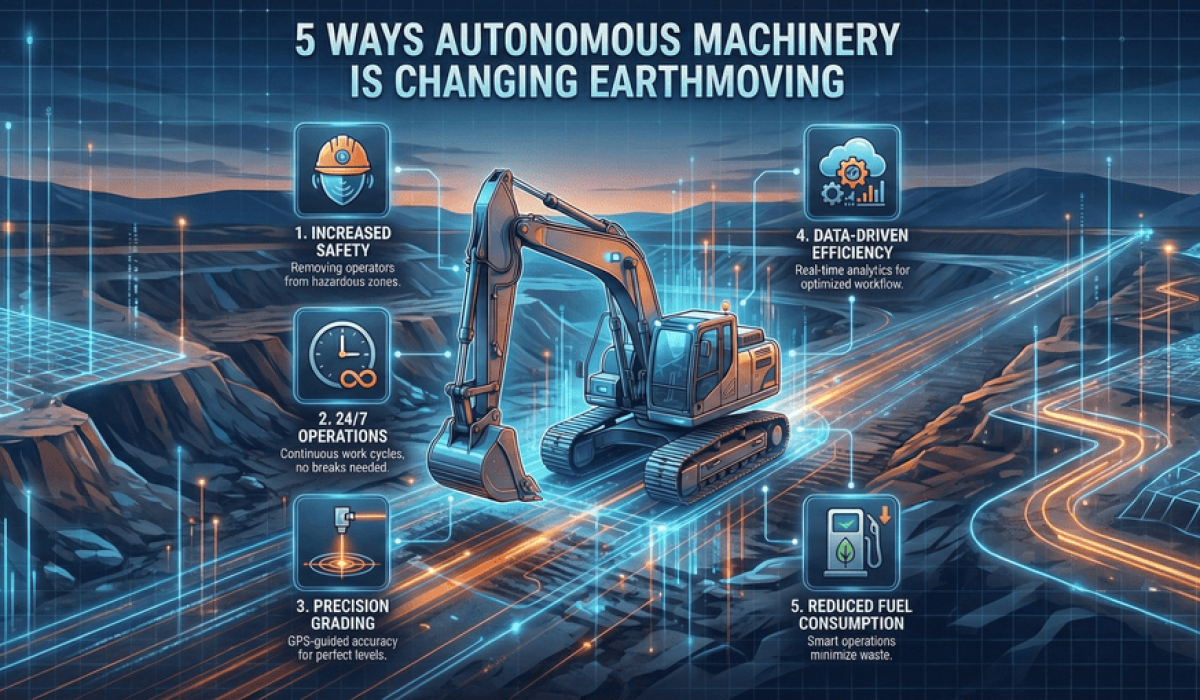

The earthmoving industry, which is an ecologically and manually skill-based market, has been powered by hydromechanical systems and, in recent years, has been transformed by a deep technological revolution that is led by robotics and Artificial Intelligence (AI).

This upheaval, whose core is autonomous machines, is not only a theoretical projection, but it is already having a tangible effect on construction sites worldwide. It is, therefore, a spectacular change for the entire industry in terms of safety, productivity, and project costs.

Once the fully autonomous excavators and dozers become widely integrated, it will be the dawn of the so-called Digital Excavation era, when machines will operate intelligently, safely, and, for the first time, with unprecedented economic efficiency.

This exhaustive study enumerates in detail the five essential ways in which the deployment of autonomous machinery is radically altering the future of digging, not only the site preparation and leveling industry sector but the entire field of construction.

1. Enhanced Safety and Risk Mitigation through Remote Operation

One of the most vital and immediate effects of the introduction of autonomous construction machinery is safety concerns. By removing the operator from the cab physically, the industry, in essence, shields against the next most frequent causes of accidents and fatalities (operator fatigue, human error, and unstable/dangerous environments).

Autonomous excavators are equipped with state-of-the-art sensors and have been programmed within the set boundaries, thus they can even be allowed to function in extreme scenarios such as unstable slopes, contaminated sites or high-risk demolition tasks.

Furthermore, this also makes true remote operation feasible, whereby an operator controls several machines from a safe and comfortably located centralized control center miles away.

This pivotal change thus tremendously diminishes liability for insurance, and safety-wise, it changes the overall safety condition of difficult projects to a high operational standard that entails proactively rather than reactively dealing with safety.

Elimination of Human Exposure in High-Risk Zones:

In parts of the work where demolition or clearing contaminated sites is involved, for example, the use of autonomous and remotely operated equipment ensures that the personnel are not directly exposed to immediate physical danger. Implementation includes, among other things, geographical fencing and collision avoidance protocols, which vary less in human reaction time than they do in consistency.

Reduction of Fatigue-Related Incidents:

The repetitive nature and long hours, which are common in excavation and grading, have been the major causes of operator fatigue and accidents that follow. Autonomy enables machines to perform without interruption since they do not undergo performance degradation, and consequently, they are always operating in a safe manner during a 24-hour cycle.

Integrated Predictive Diagnostics:

The autonomy systems that are installed in the modern heavy machinery are very deeply interconnected with telematics, and they keep on monitoring not only the machine state but also surrounding factors. Based on the instantaneous feedback related to ground stability, component temperature, or possible failure, they are capable of preventing collapses by shutting down or changing operations in advance, thus safeguarding site personnel from injuries.

2. Unprecedented Precision and Quality of work.

The practice of manual staking and relying solely on an operator’s skill for the final grade is soon to disappear. Through the use of autonomous machines, a degree of sub-centimeter soil grading to the closest level not known before can be achieved; thus, the quality and efficiency of site preparation are significantly raised.

Essentially these machines adopt advanced machine control systems that fully integrate RTK-GPS, LiDAR, and inertial measurement units (IMUs); thereby, they are able to keep on updating the real-time position of the bucket through 3D digital site models. This technology allows the flawless civilization plan to be carried out meticulously every time.

The level of accuracy in digital earthmoving reduces the excessive excavation or insufficient filling that characteristically leads to throwing of money in the form of rescheduling with less waste of material and almost total abolishment of the high-cost rework and of the low construction timelines.

Automated and Perfect Final Grade Execution:

The detailed 3D designs when uploaded, autonomous excavators are able to realize complex slopes and accurate elevations with much higher precision and speed than a human operator thus the time and expenses related to manual surveys and checks are drastically reduced. This is vital for projects with strict tolerance requirements like railway or road construction.

Optimized and Efficient Material Use:

As the systems deter unnecessary excavation, they also facilitate management of the exact quantity of the backfill and the imported materials hence there is a substantial reduction in procurement and waste disposal costs. Advanced sensing is enabling machines to label and handle materials according to density and type, thus facilitating on-site reutilization.

Seamless Digital Project Integration:

The machines are directly working from Building Information Modeling (BIM) files and digital plans thus creating a highly traceable data loop. Design updates or modifications are immediately communicated and executed across the whole autonomous fleet thereby eliminating the communication delays and guaranteeing the operations of every machine as per the absolute latest project specification.

3. Increased Productivity and Operational Efficiency (24/7 Operation)

The fact that autonomous machines can almost continuously operate in themselves is a main reason why project timelines are being shortened and overall jobsite efficiency is getting improved. While human operators have limitations in terms of shifts, breaks, and fatigue, autonomous units can be operational around the clock, throughout the week, provided that they are periodically maintained and refueled or recharged.

This nonstop operational ability of the unit, particularly during the most active construction days, results in the dramatic shortening of construction schedules.

Moreover, the operational uniformity accounts for the absence of different production rates, which depend on the skill levels of various workers; thus, production rates are now more predictable.

When a centralized Fleet Management system is used for coordination, the movements of a fleet of autonomous excavators can be synchronized with material handling with robotic precision, thus idling is minimized and throughput maximized.

| Operational Metric | Traditional Excavation (Human-Operated) | Autonomous Excavation (Machine-Controlled) |

| Operating Hours | Max 10-12 hours per day (due to fatigue/shifts) | Up to 24 hours per day, 7 days a week |

| Fuel Efficiency | Highly variable based on operator skill (idling time) | Optimized by AI; minimal idling; highly efficient cycle times |

| Grading Tolerance | Typically $\pm 1-2$ inches (manual adjustment required) | $\pm 0.5$ inches or better (systematic, eliminates rework) |

| Supervision | Direct, continuous on-site supervision of each machine/operator | Remote oversight of multiple machines via Telematics dashboard |

| Cycle Time | Variable based on operator experience and focus | Consistent, AI-optimized, and minimized |

- Uninterrupted Production Cycles: The elimination of mandatory breaks and the inherent consistency of the tasks performed by the machine result in a significantly higher daily output. Such a pace is absolutely necessary for large-scale infrastructure projects where the meeting of tight deadlines is crucial for financial success and therefore, Heavy Equipment Autonomy becomes a key investment in risk mitigation.

- Optimized Fleet Synchronization: The AI systems act as intelligent managers of the flow between loaders, haul trucks, and autonomous excavators thus they are able to ensure that all these agents are in seamless coordination. This intelligent communication gets rid of the bottlenecks on-site, minimizes the waiting time and makes sure that every piece of equipment is used at its optimal peak capacity thus the overall Return on Investment (ROI) is maximized.

- Reduced Component Wear and Tear: The autonomous systems have been designed to operate the equipment in a smooth and efficient manner thus they do not allow the sudden, impactful events which are sometimes the result of a human operation. This regularity lessens the mechanical wear and tear of the components which leads to the reduction of maintenance costs as well as prolongation of the predictable lifespan of the autonomous equipment.

4. Data-Driven Decision Making (Telematics Integration)

The decision to use autonomous machinery changes the management of the construction process into a data-science discipline.

Every autonomous excavator can be considered a compelling sensor that is continuously gathering a vast amount of data on its rate of production, place, fuel, wear, and overall cycle efficiency. The deep integration of machine control with the advanced telematics module turns the raw on-site operations into business intelligence that is immediate and actionable.

Project managers are thus given the real-time, detailed, and very local view of the performance of the earthmoving automation assets under their command, which opens the way for pinpointing the inefficiencies, very accurate anticipation of maintenance times, and quick changes of project plans. Such an abundance of control is a huge competitive advantage that permits companies to make more accurate bids and manage resources with surgical precision.

The collected data in effect serves as a reliable digital twin of the project that provides a traceable work history.

- Real-Time Performance Auditing: Through a centralized dashboard, managers can track the key performance indicators (KPIs) such as cubic meters moved per hour and fuel consumption, for the entire autonomous fleet. This immediate feedback loop provides the opportunity for instant detection of the underutilized assets or areas of the site that are in need of resource optimization, thus continuous process improvement is driven.

- Advanced Predictive Maintenance: The system identifies the changes in sensor data—like vibration and pressure—patterns so that it can forewarn the component failure days or weeks beforehand. Thus, it gives the maintenance crew the time to schedule service proactively during the planned downtime, and thus the cost and disruption of unexpected breakdowns are eliminated, and equipment uptime is maximized.

- Enhanced Cost and Time Estimation: Equipped with solid, real-world data on production rates from different completed projects, contractors are able to employ machine learning to produce very much more precise, competitive, and profitable bids for future jobs. It completely gets rid of the guessing game that is typical of traditional estimation, thus provides better financial results.

5. Addressing the Labor Shortage Crisis and Upskilling the Workforce

The acute shortage of skilled labor has become the biggest stumbling block on the way to the growth of the American construction industry. Autonomous machinery is a long-term answer as it changes the skill set requirement for the workforce of tomorrow radically.

The technology is not displacing workers completely, rather it is elevating their roles. Instead of a multitude of operators being needed in the field, the number of highly skilled technicians who are capable of managing, programming, monitoring, and maintaining advanced autonomous excavators and their centralized control systems as well as the control systems will be required by companies.

Physically demanding occupations are transformed into a high-tech, digitally oriented career, thus the earthmoving sector becomes attractive to a new generation of technologically savvy people.

Moreover, basic operational tasks can be handed over to supervised autonomous modes which enables less-experienced personnel to perform effectively while the expert personnel are engaged in high-level fleet management.

Pivoting Operator Roles to Supervisors and Specialists:

The conventional machine operator turns into a high-tech role of a remote fleet manager who from an office or mobile control center oversees the safety and performance of several autonomous machinery units. Thus it means a drastic career upgrade to higher paid, more intellectually stimulating roles that are focused on data analysis and system optimization.

- Attracting a New Generation of Talent: The use of AI, robotics, and advanced software by the industry makes the earthmoving sector a lot more attractive for individuals with engineering, programming, and data science background thus effectively increasing the available talent pool beyond the traditional construction hires.

- Standardized and rapid training on autonomous machinery shifts the focus from manual coordination to software protocols, data interpretation, and system oversight. Such a standardized digital method gives companies the ability to respond to project demands quickly by scaling up and training their workforce at a rate that is both rapid and consistent. The shift to autonomous machinery is a slow change, which basically relies on gradually advanced machine control systems and then full autonomy. Those companies that decide to be proactive in the adoption of this construction tech will be the ones to reduce labor risks, ensure high project quality and gain a competitive advantage in the modern construction market.

The future of digging is intelligent, safe, and very productive, which is made possible by the merger of robotics and AI.

Frequently Asked Questions (FAQs) about Autonomous Earthmoving

What is the difference between “autonomous” and “remote-controlled” earth moving equipment?

Autonomy in equipment means that the equipment is mostly self-sufficient in its operation; it can perform a task pre-programmed by a 3D model using AI and sensors without needing constant human control. On the other hand, remote control equipment needs a person to continuously operate it in real-time using a control unit from outside the machine.

How much does an autonomous excavator cost compared to a traditional one?

The full capital expense for a fully autonomous excavator installation (comprising sensor, software, and RTK-GPS infrastructure) is quite substantial, almost double in most cases compared to a standard unit. Nevertheless, the payback time is attained through nonstop work plus labor cost savings, work-efficiency gains, and the abolishment of rework.

Will autonomous equipment eliminate construction jobs?

No, it is planned to shift the jobs instead of cutting them. The need for physical operators will be less, but the demand for remote supervisors, telematics technicians, programmers, and maintenance engineers specializing in these complex systems will increase substantially.

Are autonomous excavators safe to use around human workers?

Yes, precise redundancies in safety that include sensor fusion (LiDAR, radar, and cameras) and geo-fencing are there for them. They are also equipped with software that enables them to be strictly operating within the limits of the zones where they have been assigned, and when a human or an unexpected obstruction is coming into their vicinity, they will automatically stop.

What level of autonomy is currently available for earthmoving machinery?

Most of the commercially available systems at present are at the Level 2 (Partial Autonomy) stage; that is they have automated blade control for grading, but human monitoring is still required. Level 3 (Conditional Autonomy) is on the way, where a machine can handle the task independently, though a human should be ready to step in.

Does weather affect the performance of autonomous equipment?

Yes, for instance, heavy rain or snow can obstruct the work of optical sensors (LiDAR/cameras). Though modern systems are also equipped with more sturdy technologies like radar and robust RTK-GPS that can maintain a very high level of accuracy even under poor visibility conditions, thus quite often they are allowed to continue their work when a human operator would not be able to due to safety or efficiency considerations.

What is the required internet/connectivity speed for operating autonomous equipment remotely?

Remote operation and fleet management require a connection that is not only reliable but also has low latency and high bandwidth, and typically it is achieved through the use of dedicated 4G/5G private networks or robust satellite systems on the work site. The low latency is essential to ensure that the remote supervisors get the control feedback instantaneously.