Prevent Costly Downtime: How American Excavator Diagnostics Tech Predicts Failures

Within the construction industry’s high-stakes environment, where tight deadlines and over-demanding projects are the daily routine, excavator downtime is not only a hassle – it is also a considerable consumption of resources, thus affecting among others project timelines, profitability, and operational efficiency at the customer’s level. Every time a machine stops due to technical difficulties means an hour of zero income, idle labor, and the occurrence of additional fees simultaneously where excavator diagnostics plays a major role.

Why Excavator Diagnostics Plays Prominent Role?

In finding a solution for this particular problem, American Excavator steps forward with one-of-a-kind excavator diagnostics technology which intends to let the repair part of the story be less reactive and more predictive, along with the maintenance part of the story being highly proactive. This groundbreaking array of instruments gives the authority of the fleet and the freedom to the service team to be able to predict the situation where the equipment may no longer function giving them a chance to prevent interruption at the pre-emptive hour and maintenance can extend the working hours of their resourceful machine.

Through the ground-breaking use of sensor technology, big data, and continuous monitoring, American Excavator not only reacts but anticipates and thereby sets the scene for preventive maintenance of the kind that keeps your excavators ready for action at all times.

The blog left through the exploration of the American Excavator’s diagnostics tech platform unravels the myriad ways that it keeps losses at bay as a potent shield, paves the way for efficiency, and provides the means for profit in construction operations at large.

Understanding the True Cost of Excavator Downtime

When an excavator is not functioning, the downtime of the excavator can lead to the delay of the whole project. What usually happens is the repair cost is only considered, remaining ignorant of all the other costs that are involved. Therefore, familiarizing oneself with the different types of expenses will help a lot in realizing the importance of the diagnostic facilities.

- Lost Productivity and Revenue: Up until an excavator can be put into service, the workers scheduled to use it will be idling. The rippling effect of this situation is the unfinished project that will be getting pushed forward in the schedule. This is a direct way to lose money since the company will be unable to bill their clients for the machinery that hasn’t been operating, translating into less income.

- Increased Labor Costs: The problem with idle equipment is that you will have to pay the workers even though they might not be completely engaged in productive work. The consequence is that the hourly labor cost will increase. Besides, it is even possible that the workers will have to put in an overtime to meet the deadlines which will be the case if the equipment is out of order for a long time.

- Project Delays and Penalties: Meeting the time schedule in performance is at the very essence of the construction contracts, shortest in terms of the latter’s number of words. Coerced by the matter, failures to do so will get the company hit with the penalty that can be both financial and in terms of reputation. Unexpected excavator downtime could be the main reason why the project is late, thus putting companies in danger of these high-priced consequences and causing harm to their reputation as well.

Advanced American Excavator Diagnostics: A Proactive Solution

American Excavator’s integrated diagnostics system provides a holistic approach to the monitoring of the health and the good functioning of the machines in a way that allows preventative maintenance.

Real-Time Data Monitoring:

The parts where the sensors are placed are carefully selected to allow easy access for the data extraction without the interruption of the operation. Some essential data attributes are engine, hydraulic system pressures, temperature variations, and component wear. The continuous monitoring allows the system to be a real-time snapshot of machine’s health without any lag of data.

Predictive Analytics and Algorithms: The data that has been collected is then sent to advanced analytic platforms which makes use of proprietary algorithms in order to figure out the patterns and the abnormalities according to which they can predict the upcoming failures. The system can become very accurate in making such forecasts when it uses not only the present historical data but also the past performance of the machine.

Early Warning Alerts and Notifications: If the system finds that a parameter is not according to the standard that it has already set or that there is a risk of failure in a particular part, it then automatically generates warnings and notifications. Those receiving the warnings may be vehicle managers, maintenance workers, or even the operator of the vehicle, thus having enough time to react in an anticipating approach.

Key Features and Benefits of American Excavator Diagnostics Tech

The excavator diagnostics tech by American Excavator comes with a collection of features aimed at easing up the maintenance and cutting the machine stoppages to minimum.

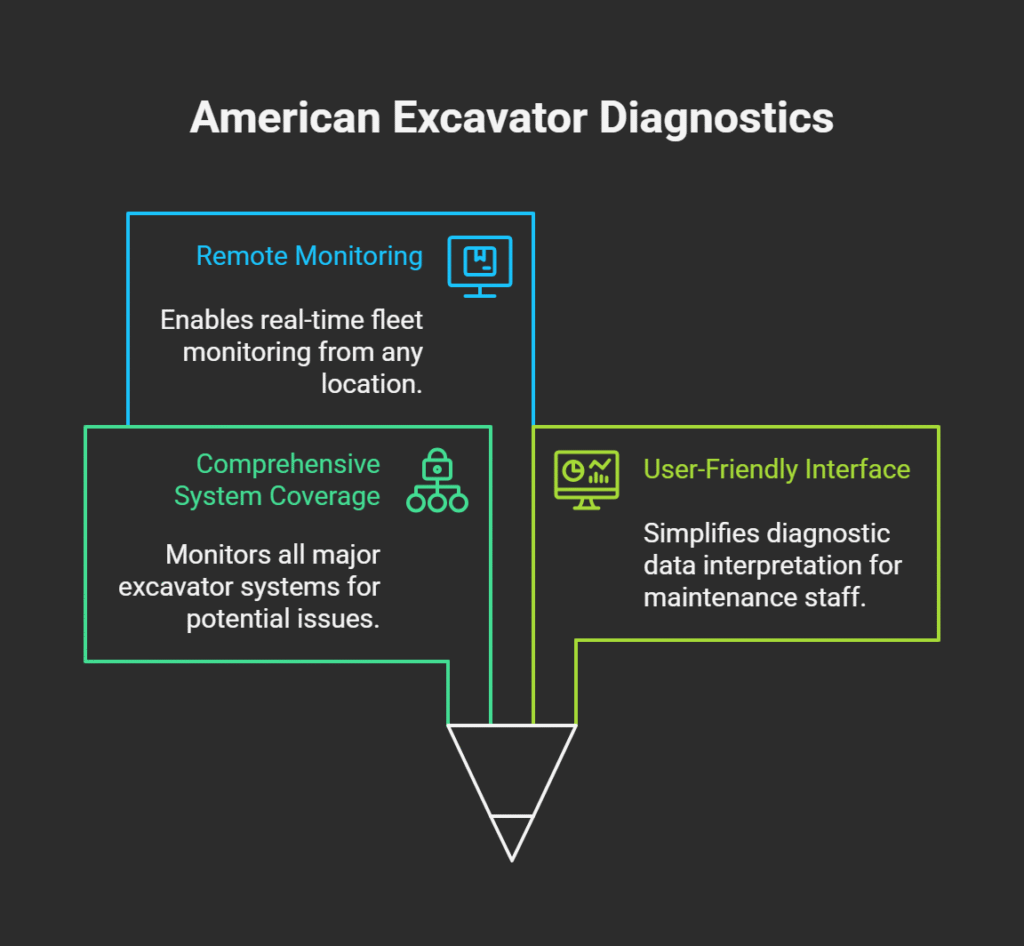

- Comprehensive System Coverage: The diagnostic system oversees everything from the engine to the hydraulic system, the electrics, the transmission, and even the parts of the excavator that are in contact with the ground. Such a comprehensive method offers the detection of problems that may occur in all these major systems.

- User-Friendly Interface and Reporting: The diagnostic information and other inputs are made available to the users through an easy to understand and use software interface. Flexible visual reports and the complete information of the equipment’s current status, past conditioning, and expected requirements of maintenance put the maintenance staff at the same level of understanding of the issue and provide them with the possibility of simple actions to be taken.

- Remote Monitoring Capabilities: Managers of fleets can at any time and from any place turn on a remote access to diagnostic data and health monitoring of the entire fleet of excavators. The fact that they are not physically close to the machines gives them the ability to be ahead of the event, making decisions in a timely manner, and allocating resources in an optimal way for maintenance, which can be done anywhere.

Prediction Implementation of the Maintenance Program with Excavator Diagnostics

Technology of American Excavator makes it feasible to move along the line of reactive repair, turning fibrilatively the mode of predictive maintenance to active one.

- Data-Driven Maintenance Scheduling: The excavator diagnostic system doesn’t just wait for the annual or biannual maintenance to pop up on the calendar. Instead, it suggests a maintenance schedule using data gathered in real time to indicate how long the duration of the working parts is, and when exactly a maintenance task should be performed. The system guarantees the staff to be aware of the need to perform as much maintenance as needed and so there is no possibility for over-intervention or well-late repairs.

- Optimized Parts Inventory Management: Through the prediction of potential component failures, the system enables more efficient planning of parts procurement. Maintenance teams can have the foreknowledge of which parts will most probably be used and plan for the time they will be withdrawn so that the work can proceed without the interruption caused by waiting for the parts.

- Reduced Unexpected Failures and Downtime: The most important goal of predictive maintenance is the great reduction of situations in which the equipment fails without being expected. Offering the possibility of fixing a defect at its very early stage, before it becomes a major one, the company is able to reduce the unscheduled downtime letting the project continue.

- Improved Equipment Lifespan and Resale Value: When the excavators are taken care of regularly and their maintenance is based on the actual condition, the diagnostic system has an indirect impact on machinery lifespan. Besides that, well-maintained machines in their latter days also obtain a higher resale value.

Getting Started with American Excavator Diagnostics

The procedure for implementing American Excavator diagnostics technology is designed to be simple and efficient, so it is easily compatible with your current fleet management routine.

Consultation and System Integration Assessment: The experts from American Excavator perform a thorough study of your requirements and evaluate the best suitable plan for your diagnostic system integration to your equipment and workflows with the help of your team.

Training and Onboarding Support: A complete training course is given to the maintenance personnel and fleet managers, who are then qualified for the use of the diagnostic software and data interpretation. Besides that, continuous support is also provided to help with any doubts or problems.

Scalable Solutions for Fleets of All Sizes: Irrespective of whether you have a small number of excavators or a large and diverse range of construction equipment, you are able to get the diagnostic solutions from American Excavator that can be scaled to your specific needs and budget.

Final Verdict:

Invest in Uptime with American Excavator Nowadays, the hectic competition among construction businesses, equipment uptime is really something of a paramount necessity. One of the most solid and effective solutions which is offered by American Excavator is its state-of-the-art excavator diagnostics technology that leads directly to the prevention of expensive shutdowns of construction equipment as well as the maximization of equipment maintenance.

By effectively implementing a proactive, data-based strategy, construction firms are practically able to cut down the rate of unforeseen failures, control maintenance costs, enhance tour of project, and thus significantly widen their net profit. In turn, the choice of the American Excavator diagnostics is actually a declaration of commitment towards the reliability and profitability of your work routine which is capable of satisfying your requirement for the times as well as the places of your hardest-working excavators.

FAQs About the Use of Excavator Diagnostics and Downtime Prevention

What types of problems are excavator diagnostics able to forecast?

- Production of exhaust gases and early wear of engine parts

- Leaks in the hydraulic system and drops in pressure

- Developing an overheating issue in a particular system

- Short circuits and sensor problems

- Transmission failure and the undercarriage which is going to get worn out previously

How is predictive maintenance different from the traditional routine of preventive maintenance?

- Preventative maintenance is carried out on a very programmatic basis, and no matter if the machinery is still in perfect condition or not, the maintenance.

- Predictive maintenance relies on the collection and processing of real-time data to “see” inside components and to reveal their true state and the parts that will fail next.

- Predictive maintenance actively eliminates unnecessary tasks and keeps the maintenance team focused on problems that can arise, leading to breakdowns if they are not fixed in time.

Is American Excavator diagnostic system compatible with excavators from other manufacturers?

Although American Excavator is the main beneficiary of their systems’ efficiency, it is possible that they are living with totally different setups to accommodate even the other way round i.e. for some models from other manufacturers by way of solutions or integrations. You need to get in touch with American staff to get the most updated information about compatibility.

What kind of data security measures are in place for the diagnostic information?

American Excavator followed the steps to make sure that its data handling process is equipped with such things like encryption, and secure data storage for the protection of the users’ privacy and to keep the integrity of the information collected.

How fast can we expect to see a return on investment from implementing excavator diagnostics?

ROI is subject to factors such as the size of the fleet, the use of equipment, and the number of breakdowns. On the other hand, many companies report the R1 in the first year after the initial investment when it happens in their situation due to the upshot of reduced downtime, lower repair costs, and operational efficiency improvement.

Does the excavator diagnostic system require specialized personnel to operate and interpret the data?

Although the training is given, a user-friendly interface is developed in such a way that it should be accessible to maintenance personnel with different levels of technical knowledge. The system usually performs the complicated part of the advanced analytics and then provides the users with easy-to-understand and implementable results.

Can excavator diagnostics facilitate fuel efficiency and operator behavior?

It is possible for some sophisticated excavator diagnostic systems to keep track of fuel consumption trends together with operator behavior (for instance, the machine is left running when not in use, the operator uses the equipment roughly). The information may be used for detecting ways of lowering fuel consumption and making the best use of the equipment through safe and efficient practices of operations.