Is Your Excavator Attachment a Bottleneck?

Every superintendent of a construction site is able to recall the specific time when everything was ready for the work, the schedule was tight, but the machine was standing still while someone was looking for a pin, hitting a stubborn wedge, or waiting for the service truck to change the excavator attachment according to the project requirements.

The Workflow Revolution with Excavator’s Engineering:

Now think about how long that hour you just described would be if it was multiplied by your fleet of machines. You will be surprised to find that you have just uncovered a secret sinkhole in your project budget. In 2025, just in the area of infrastructure projects, it turned out that attachments were the main cause of 53 % of excavator operating hours, while 67 % of contractors said that the use of traditional couplers still made it difficult for them to work.

The team of engineers at American Excavator is referring to this as the “attachment bottleneck” and they are to be congratulated for taking the principal five year break-up of the picture. The upshot of this is the installation of a workflow-centred, sensor-enabled attachment ecosystem that changes every minute of uptime into real and measurable value. This article briefly informs you about this issue, the engineering aspect, and- the most important- the practical roadmap for turning your own fleet around.

The Hidden Cost of Excavator Attachment Downtime

Even a flawless crew cannot perform at their peak level if attachment s are causing delays. Here is why the bottleneck is a larger problem than what most estimators realize:

- Compounded delays: A five-minute changeover can become a half-hour ripple effect where, for example, surveyors, labourers, and trucks are all waiting in line for their turn.

- Operator fatigue: Because manual pin changes are the only way to do the job, harsh and uncomfortable lifting, hammer blows, and re-torquing are just some of the incidents that have been linked with soft-tissue injuries and pre-mature shift fatigue.

- Under-utilised technology: No matter how advanced a BIM workflow or how efficient the 3D machine control is, it cannot generate the desired results if the iron is idle between tasks.

Market snapshot: Quick coupler systems alone will reach US $6.7 billion in 2025 and are almost expected to double by 2033 as productivity gains become the main focus of contractors.

Why Conventional Attachment Interfaces Fail Modern Jobsites

Legacy pin-on systems and early-generation couplers have been always incompatible with modern jobsite that is digitalized and data-rich. Some of the main defects are as follows:

- One-way hydraulics: These old types of constructions do not have the integrated return lines causing limited compatibility, especially with high-flow tools such as mulchers or planers.

- Zero feedback loop: There are no sensors in these systems so there is no proof of a lock, utilisation data, and predictive maintenance signals.

- Static geometry: The fixed offsets reduce the manoeuvrability of the tool and that is the main reason technical workers always have to do the sequencing very precisely within very tight work envelopes when using BIM.

- Trend alert: Tiltrotators—tools that add 360° rotation and ±45° tilt—are projected to become a US $1.5 billion market in 2025 with 7 % CAGR, thanks to their agility in confined urban sites.

Engineering the Solution: Excavator’s Quick-Switch Coupler System

With the aim of killing the downtime, Excavator did more than just re-engineer the latch to come up with a new interface; they re-engineered the entire interface:

- Dual-locking wedge + smart pin sensors not only allow the attachment to be seated with ±0.1 mm repeatability but they also let the operators see an in-cab green light before the hydraulics are pressurized.

- The self-cleaning jaw profile is equipped with tapered channels and micro-abrasive inserts that eject debris with every cycle—there is no necessity of a special tool to clean or a hammer to knock out the mud-packed couplers.

- The unified port manifold is designed to deliver high-flow, case-drain, auxiliary electronics, and a single swivel for the resting of the shear, grinder, and tiltrotator connection hence the time taken to connect is very short, in fact less than 15 seconds.

The data from the field has been very supportive to the engineers by showing that the average time for attachment changeovers has been reduced from 4 minutes to 38 seconds hence the amount of idle fuel has been saved by approximately 7 litres for each eight-hour shift.

Eco-bonus: Apart from the beneficial aspects in operations, fast couplers are also advantageous in carbon dioxide emissions, as they are one of the main metrics used in low-carbon procurement bids.

Digital Hydraulics & Smart Sensors: The Next Leap in Attachment Intelligence

Hardware is only half the revolution. Extras such as embedded electronics, ‘smart’ software and cloud access transform every tool into a point in a vast Internet-of-Things data mesh:

- The pressure and flow telemetry can, for example, spot cavitation or over-pressure conditions and push such warning signals right in front of the fleet manager’s eyes, on his dashboard.

- Recognition of the tool RFID auto-loads the correct machine control profile—stop the manual menu scrolling.

- Lifecycle counters monitor the number of hammer hits, saw hours or shear cycles, thus providing data for predictive-maintenance algorithms.

Contractors in North America who have gone for digital tiltrotators are reporting that they get double-digit reductions in rework and material wastage due to the fact that they are able to dig down to a millimetre level on the very first pass.

Workflow Revolution on the Ground:

The big productivity claims do not mean a thing unless they are backed by field proof. There are three examples from the real world, where the impact was very visible:

Urban utility install: 15 km of fibre trench; quick-switch couplers cut 2 weeks from the schedule by allowing the fast change between bucket, breaker and compaction wheel.

Wind-farm foundation: Tiltrotator + grading beam not only cut fine-grade passes from three to one but also saved the 1,700 operator hours.

River bank remediation: Hydraulic thumb + grapple changeovers enabled single-machine salvage and rock placement as a result there is no need for a secondary excavator rental.

Contractors in their testimonials state that the TCO (total cost of ownership) can be as low as 23 % in the first year if the number of machines is brought down and there is less idle time and reduced fuel consumption.

Decision Table for Choosing the Right Excavator Attachment Strategy

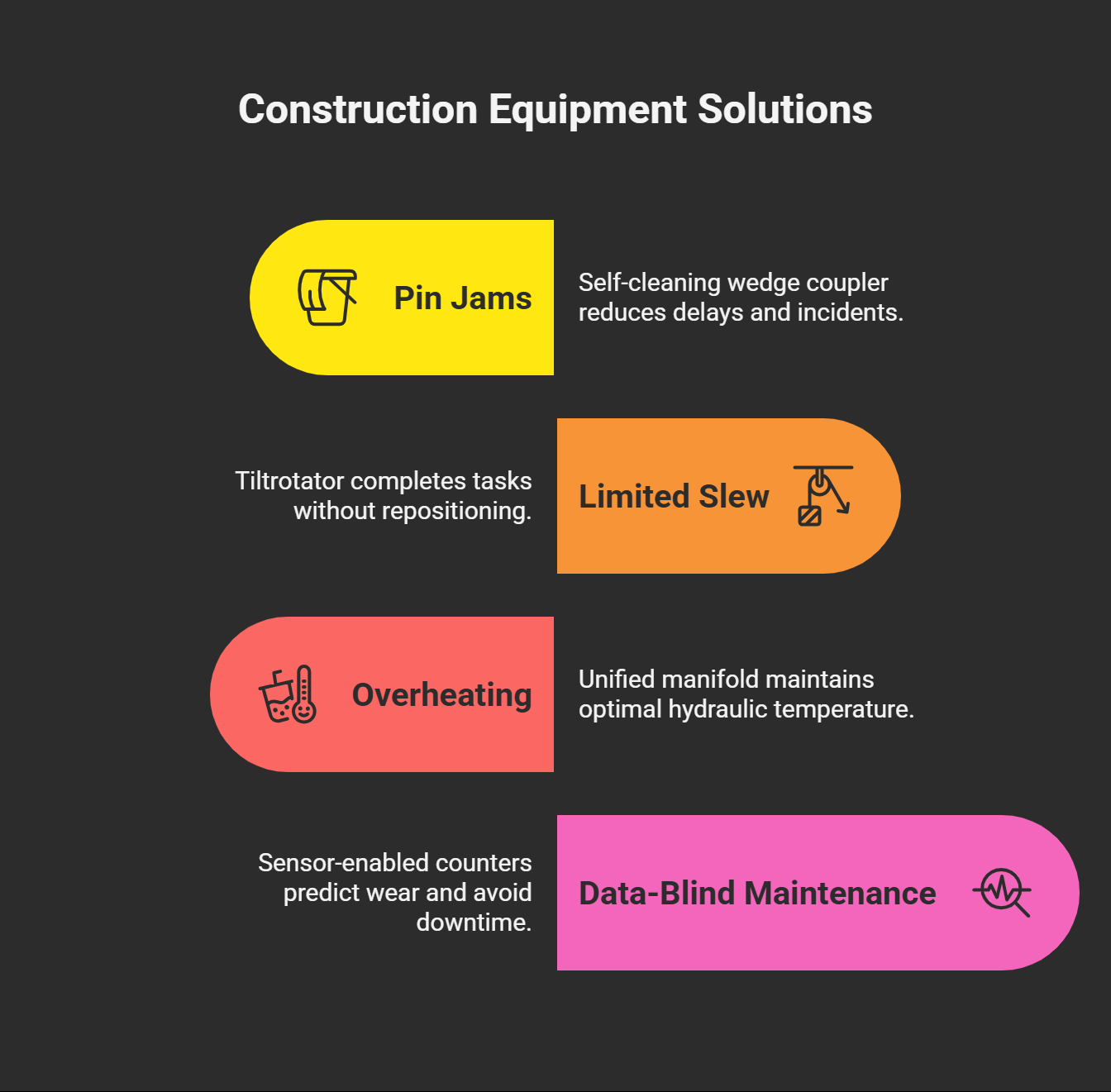

| Bottleneck Symptom | Engineering Solution | Workflow Benefit |

| Frequent pin jams in clay soils | Self-cleaning wedge coupler | Cuts changeover delays, reduces safety incidents |

| Limited slew range in tight alleys | Tiltrotator with ±45° tilt | Completes tasks without machine repositioning |

| High-flow mulcher overheating | Unified manifold with case-drain | Maintains optimal hydraulic temperature |

| Data-blind maintenance | Sensor-enabled lifecycle counters | Predicts wear parts, avoids unplanned downtime |

Tip: Run a one-week attachment utilisation audit before investing; the worst 20 % of bottlenecks often hide 80 % of lost productivity.

Implementation Roadmap: From Audit to Continuous Improvement

Jumping to new tech without a plan breeds chaos. American Excavator recommends a phased approach:

- Attachment audit: Catalogue current tools, swap frequency and average idle minutes.

- Pilot machine: Retrofit one excavator with the Quick-Switch system, pairing it with high-changeover tasks.

- Scale & train: Use pilot data to build a KPI dashboard (fuel per productive hour, cycles between service, lock-fail events) and roll out operator certification.

Most fleets are at their payback time within six months, which is very often made shorter by the sustainability credits linked to the reduced fuel consumption.

Excavator Attachment Verdict – From Bottleneck to Benchmark

Attachments are not just accessories anymore; they are the very essence of today’s excavation workflows. By doing away with the bottleneck via an engineering-led coupler system, American Excavator attachment turns each attachment change into a new money-making, safer and eco-friendly operations. The revolution is here; will your fleet be part of it?

FAQs

What is an excavator quick coupler and why will it be important in 2025?

A quick coupler refers to a latching mechanism that allows operators to switch buckets or specialty tools in a matter of seconds without exiting the cab, thus it is a solution to labour shortages and sustainability targets.

How do tiltrotators gain the productivity of compact jobsites?

In addition to 360° rotation, they offer tilt, so the exact angle can be set and the repositioning of the machine can be lessened which is the great feature for the urban utilities and landscaping.

Are the instalment of smart sensors on attachments worth the investment?

The answer is yes—telemetry is there for extreme failures, service is performed at off-peak times which increases the productivity continuously and the period of the unplanned downtime can be even reduced by 30 %.

Is it possible to convert American Excavator’s Quick-Switch Coupler to the old machines?

The system is designed to be compatible with most ISO standard lug patterns; in case there are some more antique variations, an adapter bracket covers them.

What ROI will be mine coming from switching to advanced couplers?

Results of on-site experimentations provide a payback period between 6 and 12 months through the savings of fuel, reduced rentals, and accelerated schedules.

Are faster attachment changes really the cause of lower carbon emissions?

The shorter the idle periods, the fewer the engine hours, thus the direct reduction of CO₂ is achieved—an element that is crucial for bids that are rated with sustainability metrics.

How will the excavator attachment market grow at the 2033 forecast horizon?

The global market is expected to rise from US $6.7 billion in 2025 to US $13.3 billion in 2033, with automation and smart tech use as the main growth factors.