Beyond the Brochure: Why American Excavator Machines Outperform the Competition

Today’s construction and earthmoving industry demands purchasing decisions that go beyond a brochure’s checkboxes. It’s no longer about the features a piece of equipment offers or whether the shiny salesperson sounds convincing. It’s about finding a perfect American excavator partner who is honest and reliable in the promise of success every day and in the most demanding workplaces which can be provided by American Excavator.

American Excavator believes in doing things better than others. We are with our customers in the real sense as we always pursue and deliver the best products. Hence, our physical products and measurable success provide a real competitive edge.

Latest Statistics:

The US excavator market is estimated to be worth just under $11 billion by 2030, and it is a highly dynamic, diverse, and growing market driven by investments in infrastructure and urbanization. Manufacturers are largely optimistic about factors like the availability of advanced technological products and the acceptance by large construction firms.

According to the latest machineries that are highly efficient, construction materials, and capital goods, the U.S. excavator industry is predicted to have an average annual growth of 6%. American Excavator is a global front-runner in excavators and equipment manufacturing, paying particular attention to benchmark performance and customer satisfaction.

We believe that high-quality lies in innovatively designed and meticulously manufactured excavators having robust characteristics and are flawless in their working, the American Excavator which is a prime example of US manufacturing.

The American Excavator Advantage: Best Performance Guaranteed

Performance does not refer only to the ability to do a lot of work. Efficiency, precision, speed, and uptime are the concepts that are part of the whole performance vision. The purpose of our excavators is to cover all the angles to which the operation is related, thus your task to move more material, execute faster projects, and at the end of the day, be more profitable becomes a reality. The technology on board means business.

1. Optimized Hydraulic Systems:

The core of the American Excavator machines is a hydraulic system, which is carefully designed for each model. Unlike our peers, we do not trade hydraulic effectiveness for other parameters.

Instead, we employ intricate very high-speed hydraulic systems that bear huge power and also exhibit great agility whenever the need arises. This is then translated to shorter delivery cycles, the ability to control the attachments more accurately, and of course, the ability to handle the most demanding digging tasks comfortably.

Moreover, our systems significantly reduce the energy dissipation and consequently help become more durable machines.

2. Robust Engine Integration:

Our selection of an engine supplier is one of the drivers for the integration of an engine. We have deep respect and understanding of the manufacturers of powerplants, and they offer us the right type of engines that fully adjust to the hydraulic pressure of our excavators.

This bonding results in the most effective and cleanest combustion of fuel, and it is also followed by the emission process. With no regard to the load that is being carried out, these engines exploit a minimum of the resources, and if the model is not in line with a high level of work from the start, there would not be any disruption in its action and performance for the whole period of the mechanical output.

3. Superior Digging Force and Reach:

Our excavators are not only meant to be the superpower in digging and reaching. They have been designed with the best digging force and reach in class. This feature will enable you to make the earth deeper, you will lift the earth to greater heights, and you will transport the material more quickly.

A mere expansion of the survival kit, it is the stability of the machine, the equivalent power of the cylinders, and the set-up of the employment situation that mean the most in terms of efficiency and consequently the highest on each job. When reading about the latest SMART construction machine in a construction project, product manager will inform you that the boom arm is the main driving force.

Durability and Reliability: The American Excavator Promise

One of the most critical factors that determine investment in heavy machinery is the out-of-service rate. For every hour the machine does not work due to some kind of breakdown, the company faces the possibility of making no profit as well as not being able to keep up with the project schedules.

Durability of the frame, booms, and arms

The American Excavator machines invariably top the list of the most durable and reliable machines, which is a direct consequence of our constant dedication to the production of high-quality American-made equipment, and rigorous testing procedures we adhere to.

Heavy-Duty Steel Construction: We take frames, booms, and arms, which are made of high-strength, wear-resistant steel, further strengthened at the most vulnerable points with abrasion-resistant steel. We use sophisticated welding techniques and stringent quality control to ensure that the structure can be used in the toughest environments and the most severe applications, such as the mining of rocky quarries and the demolition of the most challenging structures.

Selection of high-quality components: We never compromise when it comes to component selection. We are talking about selecting materials for hydraulic pumps, motors, electrical systems, and undercarriage parts, in fact, the best of the best, which we buy selectively and with a lot of care from reliable suppliers. This very through-going selection process is the leading factor in the overall lifespan and reliability of our machines. Just to be on the safe side, our machines likewise repetitively go through rigorous use without any premature damage or malfunction.

Evaluation of strength and control standards: Every machine is tested to its limits and put through its paces in a wide variety of controlled and monitored conditions. In our plant, every machine has to prove its productivity, stability, and quality through performance tests, stress tests, and inspections. A guarantee of product quality brings you the added benefit of getting a machine that is fully operational, at all points after manufacturing, and thus, there will be fewer failures occurring on the spot.

Innovation at Work: Technology That Drives Efficiency

The construction industry is up for a shake-up every other day, and so are our machines. American Excavator is a pacesetter in integrating the latest technology that does a lot in enhancing performance, ensuring safety, and at the same time, betters the operational efficiency. We are convinced that real innovation creates practical effects and brings value to our customers.

- Advanced Telematics and Remote Monitoring: Our fleet of excavators is supported with supermodern telematics systems that offer location tracking, operational hours, fuel consumption, and diagnostic codes in real-time. This not only has enabled you to monitor your fleet from a distance but also perform the preventive maintenance of the so done equipment, thus avoiding the possible problems before they reached unmanageable level that also without the need of physical touch. Moreover, this way, you can take immediate action if your machine underperforms.

- Intuitive Machine Control Systems: Our machine control systems are designed with 3D and GPS so that the operator can accurately dig and grade within millimetre tolerance. These high-technology systems give the chance for the operator to cut through to a precise point without varying and thereby reduce the need for additional material, lesser project duration, and at the same time, rework is curbed. This technology is a disruptor for construction projects involving major volumes of earth, thus ensuring everything is on point and surprisingly quick.

- Enhanced Operator Comfort and Safety: We are aware of the fact that the operator needs to feel safe and comfortable in order to be able to give their best, so they are provided with the green environment to work in. For instance, our cabins are cool in summer and warm in winter, have anti-vibro seats, have a good visibility thanks to the camera at the back, the LED lights, and the systems that give warnings. All these modern features are either part of or available as an option and they really help employees be in peace and work effectively without endangering themselves.

Tailored Solutions for Every Challenge

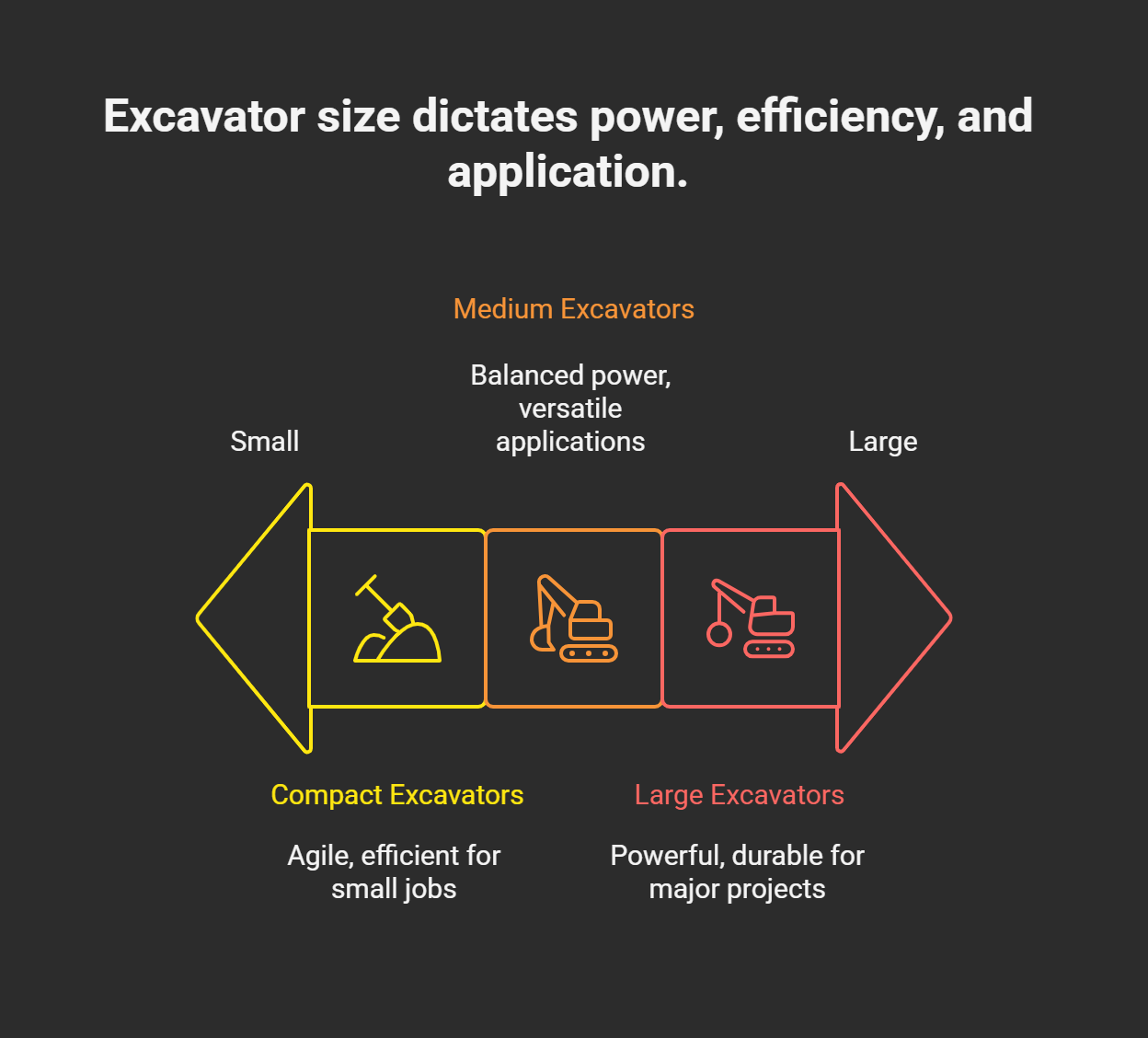

American Excavator has an extensive inventory of machines, ranging from small excavators that are ideal for city projects and landscaping to big excavators that are specially built for the mining and infrastructure construction businesses. The wide range of products that we carry guarantees that we have the machine you need, irrespective of whether you have a small or large project, or your project is simple or complicated.

| Excavator Type | Key Applications | Performance Highlights |

| Compact Excavators | Landscaping, utility work, residential projects, tight access sites | Agile maneuverability, precise control, excellent fuel efficiency for smaller jobs |

| Medium Excavators | General construction, road building, site preparation, demolition | Optimal balance of power and efficiency, versatile for various applications |

| Large Excavators | Mass excavation, quarrying, mining, major infrastructure projects | Unmatched digging force, high-volume material handling, extreme durability |

Versatile Attachment Compatibility: Our excavators are multifunctional and are thus capable of dealing with a wide range of attachments. The quick coupler systems and auxiliary hydraulic lines equipped with the excavators ensure that the attachments are connected quickly and the maximum scope of additional implements is guaranteed. Our machineries are flexible and can handle assignments including but not limited to hydraulic hammers, grapples, special buckets, and pulverizers. The above-mentioned capabilities allow you to save money by conducting multiple tasks with one piece of equipment at your site.

Customization Options: We know that each work environment has its own unique nature and requirements. Therefore, American Excavator provides a diverse range of customization options: from tough guarding against demolition to extra-long reach configurations needed for certain diggings. We carry out the whole process in a close cooperation with you so that we can be sure that the machine because it’s perfect for the tasks at hand.

Unmatched After-Sales Support: We commit ourselves to our customers long after the sale is over. Our pride is rooted in the provision of extra-ordinary after-sales support services that consist of spare parts being available at any time, specialist service team, and comprehensive training programs. This only guarantees that your American Excavator machine still performs well and stays totally efficient for its entire life span. Our extensive network of dealers all over the United States is the source of the help which is always nearby.

American Excavator Difference: A Promise of Quality and Neighborhood

When you opt for American Excavator, you do not only make a business decision, but you also make a contribution to local communities and the USA as a whole. Our machines are not only designed, engineered, but also manufactured in the United States, which is a source of pride, thus benefiting the local economy and setting the highest standards of quality.

Proficient American Workforce: A team of engineers, technicians, and assembly workers, who have a wealth of experience and dedication, operate our manufacturing facilities. This example of knowledge is a fundamental source of the resilient and effective performance of our products. Moreover, it shows a practical way to solve the challenges of heavy equipment.

Strict Supply Chain Regulations: We impose rigid rules on our supply chain, and we show a preference for domestic suppliers of components wherever applicable. This action is not only responsible for the quality and availability of our parts but it also, in crisis time, can reduce the pressure on our production which can result in undisturbed operations and eventually will lead to prompt machines and spare part delivery.

Beyond the Initial Investment: Understanding Total Cost of Ownership

As the original purchase price only represents one of the costs, well-prepared business owners still ought to realize that the good ownership equipment costs are sounding lower. American Excavator machinery is built to ensure a lower total cost of ownership (TCO) by providing better leveraging of energy, reducing the need for maintenance, and having an excellent selling price, apart from providing outstanding performance.

Fuel Efficiency That Matters: Our well-organized engines and energy distribution units are purposefully crafted with fuel that consumes at the rate of less than one unit of fuel per hour of operation, therefore, meaning that over the longest time possible, a considerable amount of money is saved. In an industry where fuel is a key cost of operation factor, this efficiency directly relates to a firm’s healthier financial position.

Extended Service Intervals and Easy Maintenance: The machines’ design is focused on the concept of simplicity in maintaining of machines. This is achieved by the incorporation of easily reachable service points, strong, long-life components enabling a double period of maintenance thus giving the customer less time and saving money. Thus, with the machines, the customer faces less downtime and saves more.

High Resale Value: The image that American Excavator machines have for being the most reliable, sustainable, and all-around performers in the market has created a perfect relationship with their value in the second-hand market. When the time comes to make an upgrade or add new machines to your fleet, rest assured that your American Excavator purchase will still be of considerable value and, hence, remain financially viable.

The Future of Excavation is American Excavator

Every day, construction workers want more efficient, reliable, and technology-integrated equipment, and American Excavator remains the industry leader despite the competition. The firm never rests, searching for new ideas and improving earthmoving equipment. Our top priorities are equipment performance, longevity, and client happiness. Buying an American Excavator machine is a long-term, win-win scenario that will propel you to the top for years.

Go beyond the catalog. Contact our pleased clients, tour our facilities (if applicable), and meet with our experienced staff to feel the American Excavator difference. The time has come to discover that our equipment exceed your expectations, are more productive, and help your company grow.

Frequently Asked Questions (FAQs)

- What sets American Excavator machines apart from other brands on the market?

American Excavator does not just use a single method to separate from all other brands but rather a mix of super quality in the manufacturing process, the result of the highly optimized hydraulic systems around added power, the advanced telematics which make real-time monitoring possible and the impressive emphasis on operator comfort and safety. We at American Excavator are not just contented to assemble as we go further to engineer our products for maximum efficiency and also for longer life.

- How do American Excavator machines contribute to lower operational costs?

Our machines are intentionally made to be fuel efficient by the smart integration of engine and hydraulics, having prolonged service intervals due to the use of durable components, and causing minimal downtime through our strict quality control. These aspects will result in the ownership cost of the machine over time to be much lower than otherwise.

- What technological progress in American Excavator machines am I able to enjoy?

The list of the features you will have includes the up-to-the-minute telematics system for fleet management and diagnostic capabilities, very convenient machine control systems for accurate digging and grading, and operator interfaces that have been improved to both productivity and safety. Here we talk about technologies that come with proper and efficient analytics and simplify the process of operations.

- Does American Excavator pay attention to environmental issues?

Yes, American Excavator fully complies with sustainable practices. Our machines are designed in such a way that they either meet or surpass emission standards, and we continually search for improvements in fuel efficiency and alternative energy sources. Our production techniques also foster sustainability such as the stewardship of natural resources and the reduction of waste.

- How are parts and service arranged for American Excavator machines?

Speaking of the distribution system, American Excavator owns a wide-spread network of authorized dealers which are located all over the U.S. This has made it possible for us to have genuine parts and expert service wherever we are. Our technicians are factory-trained and ready to respond, and so they will provide sudden and quick assistance as well as guarantee the minimum downtime.

- Can American Excavator machines be tailored for particular job requirements?

Yes, indeed. We have a variety of customization options such as special guarding for specific applications (e.g., demolition), long-reach booms, and a number of compatible attachments. Our team assists you in order to fit the machine to the job’s unique requirements and make it ideal for your continuation of the project.

- What is the standard resale value of an American Excavator machine?

On the market for second-hand equipment, American Excavator machines are still highly regarded for their long-lasting durability, reliability, and consistent high-quality performance and therefore, they usually trade at a high resale price. This will certainly ensure the continued value of your initial investment and also when it comes to selling.