One of the most frequently asked questions that contractors, landscapers, and construction professionals always ask when operating a mini excavator is, “How much fuel does your mini excavator use?”

Concrete technology has evolved tremendously; however, if you stumble upon a road under construction, it will most likely be the best choice to keep off the old route, especially if you prefer cleanliness and high speed of transport. Fuel monitoring offers solutions for various types of mini excavators with different specifications.

Furthermore, it’s worth mentioning fuel monitoring also plays a significant role in tax reduction. For example, a fleet operator can minimize the amount of fuel by GPS tracking, and subsequently, he or she will know for sure if the returns are real or not.

What Is a Mini Excavator?

Mini excavators, as well as compact excavators, are versions of standard excavators which are of smaller size. Usually weighing from 1 to 10 tons, the machines are suited to small to medium construction projects like trenching, digging, grading, and demolition.

Their portability is a feature in need, hence the nature of being strong in carrying out tasks such as urban, rural, and other heavy-duty landscapes; utility, such as plumbing and electrical fittings; or even a combination of one or more. They can be connected with several extensions contributing to the broadening of their use.

Average Fuel Consumption of a Mini Excavator

The fuel consumption is largely influenced by the size of the excavator, the type of engine, the working intensity, and the operating conditions. Here’s a general breakdown of what to expect:

| Mini Excavator Size (Tons) | Average Fuel Usage (Liters/Hour) | Gallons/Hour |

|---|---|---|

| 1–2 Tons | 2 to 4 L/hr | 0.5 to 1.1 gal/hr |

| 3–4 Tons | 5 to 7 L/hr | 1.3 to 1.8 gal/hr |

| 5–6 Tons | 6 to 9 L/hr | 1.6 to 2.4 gal/hr |

| 7–10 Tons | 8 to 12 L/hr | 2.1 to 3.2 gal/hr |

Quick Reference:

- Light-duty work: The light-duty work requires lower fuel usage, and while describing it as an example, the instructor mentions trenching in soft soil.

- Heavy-duty work: Doing heavy-duty work uses more fuel, a good example of which can be excavation in rocky terrain.

Key Factors Influencing Fuel Consumption

1. Engine Size and Type

Bigger sizes of engines consume more fuel but also produce a lot more power stuff. Tier 4 Final diesel engines are the most common and are designed to meet the emission standards plus save fuel.

2. Operating Conditions

Easy routes, uphill tasks, or heights are the types of conditions that can be more fuel-consuming. These conditions will lead to engine overload resulting in a significant fuel consumption rate.

3. Operator Habits

Good drivers don’t idle unnecessarily and try to be at the optimal rpm all the time. These can save them the power consumption worth noting as the figures are huge.

4. Hydraulic System Efficiency

Systems that are older and not properly maintained can take on the same job with more power and thus cause the usage of more fuel.

5. Attachments and Load

By applying enormous or high-energy tools such as the augers, breakers, or thumbs, more energy has been consumed. Meanwhile, the higher consumption of fuel translates to high fuel usage.

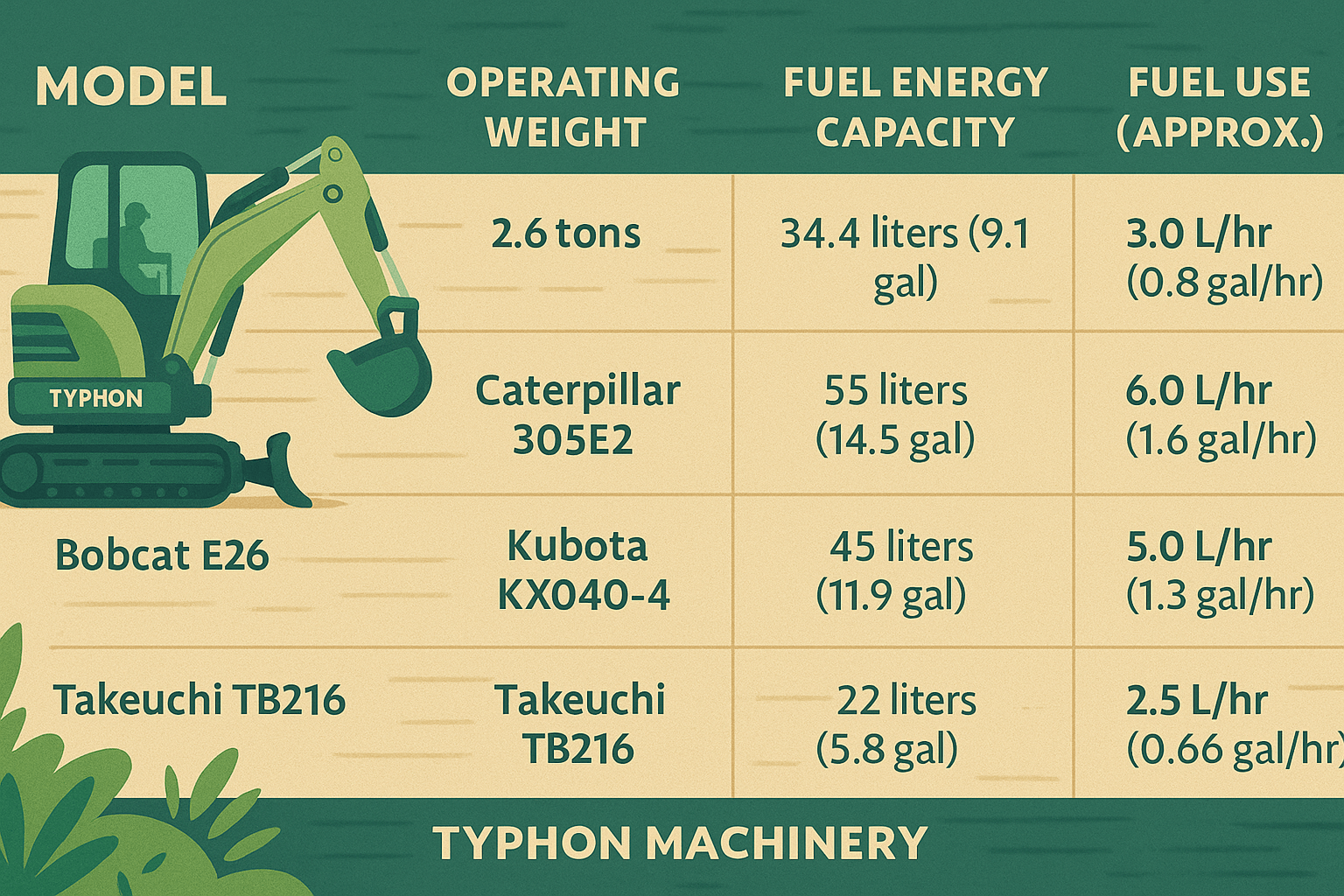

Fuel Tank Capacities of Popular Mini Excavator Models

Here’s a list of mini excavator brands and their fuel tanks’ capacities:

| Model | Operating Weight | Fuel Tank Capacity | Fuel Use (Approx.) |

|---|---|---|---|

| Bobcat E26 | 2.6 tons | 34.4 liters (9.1 gal) | 3.0 L/hr (0.8 gal/hr) |

| Caterpillar 305E2 | 5.2 tons | 55 liters (14.5 gal) | 6.0 L/hr (1.6 gal/hr) |

| Kubota KX040-4 | 4 tons | 45 liters (11.9 gal) | 5.0 L/hr (1.3 gal/hr) |

| Takeuchi TB216 | 1.6 tons | 22 liters (5.8 gal) | 2.5 L/hr (0.66 gal/hr) |

These figures are averages based on mixed-use conditions. Actual consumption may vary.

These figures represent the average values of fuel rate, and they are all made by different manufacturers and various models.

So you are advised to also check the information with the supplier to get precise figures.

How to Calculate Fuel Costs in Mini Excavators?

For the full gas price, the following formula can be used:

Fuel Cost = Operating Hours × Fuel Consumption (L/hr) × Cost per Liter

Example: If the diesel unit you use for digging (3 tons) consumes 6 liters/hour and the price of a liter of diesel is $1.25, the gas cost can be estimated in this way:

8 hours/day × 6 L/hr = 48 liters/day – 48 × $1.25 = $60/day

Within 20 days, you will have spent

$60 × 20 = $1,200/month

These data present clearly the significance of controlling and optimizing fuel usage.

Diesel vs. Electric Mini Excavators

Electric mini excavators are winning hearts in the market as environmental regulations get increasingly stringent. Let me tell you, briefly, how they differ:

Electric mini excavators are winning hearts in the market as environmental regulations get increasingly stringent. Let me tell you, briefly, how they differ:

| Feature | Diesel Mini Excavator | Electric Mini Excavator |

|---|---|---|

| Fuel Type | Diesel | Electricity (Battery) |

| Operating Cost | High | Low |

| Maintenance | Moderate to High | Low |

| Noise Levels | High | Low |

| Emissions | Yes | None |

| Range | Unlimited (with refuel) | Limited by battery life |

Key Insight:

Electric excavators, despite the fact that they do have low operational costs, mostly are at present more costly at the point of purchase and are a perfect choice for small-scale jobs that need a very short amount of time or for the space indoors.

How Much Fuel Does Your Mini Excavator Use? Measure Fuel Efficiency.

How many gallons of gas are needed to mow an acre of grass?

Fuel efficiency is not merely a question of liters per hour, but liters per hour of the actual work done. Taking a look at the following measures might be helpful:

- Liters per meter of trench

- Liters per cubic meter of earth moved

- Liters per hour of productive work

Newer models are equipped with telematics and fuel monitoring systems which automatically capture and deliver this information.

Tips to Improve Mini Excavator Fuel Efficiency

1. Minimize Idling

It is estimated that idling consumes 1-2 liters of fuel per hour without any productive work. It is recommended to shut off the engine if it is inactive for more than 5 minutes.

2. Regular Maintenance

- Install air filters

- Change defective hydraulic components

- Examine fuel injectors and oil

3. Optimize Workflows

Digging the least possible or one–time loading régimes are planned during the flow-minimizing unnecessary moves and loading cycles.

4. Use Eco Mode

One feature of modern mini-excavators is the “Eco” or “Smart” setting specifically established to take optimum advantage of the ingenuity of the motor to give the driver even greater fuel efficiency.

5. Right-Size Your Machine

Usage of a small excavator must not be used beyond its capacity and likewise a large excavator should not be used for a very small job. Match machine size to the task.

Conclusion: One should take waste of fuel only as the necessary renewing of the sources of energy into account.

Future of Fuel Use in Mini Excavators

- Hybrid and Electric Technologies: The advanced battery and hybrid technologies will lead to a more eco-friendly and efficient future.

- AI and Automation: Technologies like AI-assisted excavation, telematics, and automatic idle shutdown are ensuring the lowest fuel consumption besides their role as a monitor.

- Sustainable Fuels: In some cases, manufacturers are testing biofuels and synthetic fuels that may not only reduce the CO2 emissions but also maintain the fuel efficiency of the vehicle.

Final Thoughts

Use of fuel is one of the most significant costs that the mini excavators incur in their operation. Through becoming aware of the fuelling habits of your machine, knowing what you can do to solve the issue, and methods of saving, you can save thousands of dollars in a year. Also, you can make your machine work longer.

Commit to sustainability in the whole process, from selecting the most suitable machine right down to the training of the operators and making use of smart technologies. Reducing fuel consumption is a daily task through the implementation of this strategy.

If you would like your website to have this content posted or you need the format or pictures like diagrams, infographics, or calculators that are part of the article, you can tell me!

FAQ section

How do I calculate mini excavator fuel consumption per project?

To find the fuel usage per project, use the formula:

Total Fuel = (Operating Hours × Fuel Consumption Rate)

To get the amount, just multiply the result by the fuel cost per liter/gallon. For better accuracy, some other factors such as the idle time and daily changes can also be included.

What is the fuel efficiency of diesel mini excavators compared to electric ones?

Diesel mini excavators are the best choice for longer, more intensive projects. However, electric mini excavators use less fuel over short time due to the absence of idle time, zero energy expenses and less wear.

Do mini excavators use more fuel in winter?

Yes, they definitely do. The low temperatures prolong the heating up of the engine and at the same time cause hydraulic fluids to thicken, thus there is a higher energy output. Pre-heating and using winter-grade fluids are effective measures in reducing this effect.

Can GPS and telematics help track fuel usage?

Definitely, they can. Many of today’s mini excavators are linked to GPS and telematics systems like Cat Product Link, Komtrax, or Bobcat Machine IQ where online fuel usage status and analysis, engine management reporting, and operator efficiency can be accessed.

What fuel type is best for the Mini Excavator?

Ultra-low sulfur diesel (ULSD) is the fuel that is used by most mini excavators due to stricter emissions standards. The use of good diesel will prevent clogging of the injector and will lead to an efficient combustion process.

How long can I operate a mini excavator on a full tank?

Once the tank is full, mini excavators can be used for operation for quite a while, Which engine tuning aspects determine the reduction of fuel usage in mini excavators? What are all the various aspects of a tuning procedure that optimize an engine’s performance and ensure it does not work to