10 Key Factors to Consider Before You Buy a Mini Excavator

If you are currently looking to buy a mini excavator and are finding the decision too tough, this is _ the perfect guide that can help you narrow your options down to 10.

A mini excavator purchase is considered one of the major investments in the business. Therefore, it is highly advisable to seek professional advice. The range of factors, beginning with the size suitable for your work and the machine’s power and versatility, will all be thoroughly discussed.

In this writing, we will talk about the different types of mini excavators and their performance and overall potential. We will also go deeper into aspects such as operating weight, digging depth, and bucket capacity so that you understand how they affect your work.

Furthermore, we will highlight the maintenance needs and new technological aspects relating to the most recent mini-excavator models. With the help of our guide, readers can be equipped in what to look for and, hence, will be in a position to identify the right machine that matches their specific requirements.

Do not stress over the buying process! Let’s together fast-track the right mini excavator to kickstart your construction projects.

Advantages of Owning a Mini Excavator

To own a mini excavator means the favorable condition of performance has come as a result of the fact that there are numerous benefits that a construction and a landscaping project may face, which encompass better productivity as well as efficiency. Versatility is one of the key benefits that these machines have.

One of the significant advantages of owning a mini excavator lies in its multifunctional nature, and the excavators can handle any given task, from digging and leveling to lifting and demolition. The flexible usage of the mini excavators makes it possible for users to do many things at a go and in a quicker manner.

Furthermore, it is one of the reasons that the machines are so attractive that they are able to operate in locations that are inaccessible to larger electric shovels, e.g., urban projects or residential renovations.

One more major advantage is mini excavators for small businesses as opposed to the large ones, with their lower running costs. Usually, mini excavators use a smaller amount of fuel and have lower service needs, which ensures cheaper operation expenses. In most cases, their engines are smaller but still efficient, so the owners can benefit from a lower fuel consumption rate without any loss in power.

Moreover, some of these machines are environmentally friendly because of their fuel-efficient systems and variable speed controls, which automatically save the energy. All these factors together make them the first option for cutting the costs of small and medium-sized enterprises.

The compact size of mini excavators also provides the owner with transport convenience, a valid point for the purchase of them. As a result of their low weight and small dimensions, they are not a problem when it comes to transporting, i.e., not a problem if they have to be moved from one workstation to another.

They can usually be lifted onto standard flatbed trailers and do not require transportation carrying a special condition. This fact makes it possible for contractors and construction managers to save a lot of time and energy by moving equipment between sites in the most effective and productive way without facing the problem of transition time.

In addition, the compact size of these mini excavators and the related quick transportation are the factors that allow companies to diversify more in terms of projects and thus lead to an increase in their business competitiveness.

Types of Mini Excavators

If you are on the lookout for mini excavators, there are various types that are available and are designed to serve different needs and applications, so it is very important to be well-informed. Among the popular ones are conventional tail swing, zero tail swing, and compact or reduced tail swing models.

Conventional tail swing excavators are generally stable and comply with the basic principles of engineering, i.e., statics. Thus, they can be used in bigger job sites such as those in city centers and harbors where space is not a concern. There, they can provide the user with large digging radii and good lifting capacities, thus becoming convenient for heavy-duty tasks.

On the other side, zero tail swing mini excavators have a specially tailored design that permits them to rotate 360 degrees without their tracks extending further. The most important feature of these excavators is their ability to operate in narrow spaces, where the possibility of being in close proximity to walls or other buildings is the biggest advantage aside from risk-free operation with the machine counterweight.

The increase in the use of these machines is evidenced by the number of contractors and gardeners who have taken up practice within city limits, where the parking lots are already running at maximum capacity. The machines are specifically designed to reduce the chances of damage to nearby areas, therefore making them the first and only choice for many users.

Compact or reduced tail swing mini excavators are a combination of traditional and zero tail swing models. This is actually neither here nor there; that is, the characteristics of the new models allow them to be used in places more typically accessed by the traditional models, namely the job site and the roads, while still keeping their previous functionality of being able to pass through narrow places.

Minding the fact that these kinds of machines carry out more than one task and thus give an outstanding performance, it is possible that decanting a trench or restoring the landscape to its original state are the projects for which they will be most suitable. Knowing well the differences between these devices is, therefore, a must when deciding on the one that satisfies your special needs so that you do not put your money into a poorly suited tool.

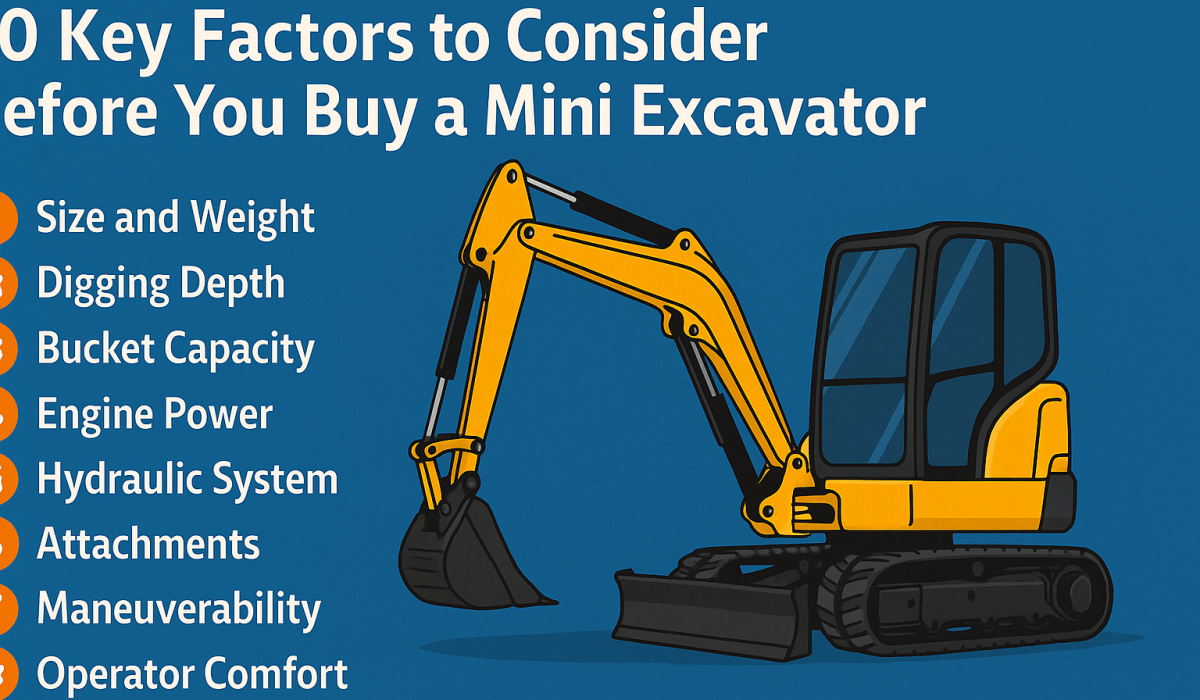

Factors to Consider Before Buying a Mini Excavator

One should know that some factors must be weighed in advance of the decision to buy a mini excavator to see if your choice will be of use to your operational needs and thereby shape the whole nature of your venture if the scale is indeed major. The first step should be a careful evaluation of the workload and the types of jobs the machine can do most effectively.

Thus, one should really think about whether it’s the case of the heavy digging or grading or the other alternatives and how often, and therefore, should the help of a machine take place. Through this, the power required for the machine comes out of the number of work plus the …

Size and weight are indeed two crucial aspects that we cannot overlook when we have to pick the right mini excavator. The small mini excavator type comes in different sizes, and the choice of one with an appropriate size would give you a great effect on your ability to operate in constricted spaces and move the machine between work locations.

The machine’s dimensions and weight limitations must be looked into carefully. It’s also very important to examine the dimensions and weight limits of the mini excavator and make sure they fit both your working conditions and any transport regulations to be faced on your way.

And you must not miss this—tool kits and multi-functionality of the machine are worth being taken into consideration last. A mini excavator can handle a great number of attachments, such as buckets, hydraulic breakers, and augers, that can significantly expand the excavator’s functionality. If you choose a mini excavator, ask about the possibility of different equipment being together and their availability in your area.

Size and Weight Factors

The machine’s performance, maneuverability, and transportability are the primary functionalities influenced by the size and weight of a mini excavator when choosing it.

The width of the excavator also determines the number of areas it can access, especially in urban or confined positions. Most urban, and more so residential, sites with limited space require a smaller version of the machine to leave a minimum footprint so that neither the property nor the existing structures are damaged.

In other places, more massive machines are used where there’s a bigger area to be dug or where stability is of greater importance.

Weight is an important aspect that defines the stability and the strength of the machine. A mini excavator, which is heavier in most cases, provides more stability because it is capable of holding the material and lifting it up.

On the other hand, such an increase in weight can restrict the movement of the machine, with the result that it is no longer possible to do the excavating and transporting of the material.

Thus, the mini excavator has to be heavy enough to accomplish the task, and at the same time, it has to be easily maneuverable and accessible to fit the specific job site requirements. Learning the definition of why weight distribution is necessary and how the center of gravity is influenced by it can add extra value to your decision-making process.

The first step you should take apart from the above is to research the transport regulations for the type of vehicle that will transport the mini-excavator from one place to the other.

The heavier mini-excavators might make it necessary for them to be moved by specialized trucks that may be expensive in the overall transport process. Once the transport facilities get restricted and the overland transport rules of the machinery remain unknown, then choosing the right size and weight of the mini-excavator would not be difficult.

Engine Power and Performance

The engine of the mini excavator is the force that propels the machine, and it is of major significance in determining the efficiency of the machine. The power is usually expressed in terms of horsepower (HP) or kilowatts (KW), and it predominantly tells the aptitude of the tractor to work with the tools to the last specification, i.e. carry out even the most difficult of tasks without any problem.

You have to ensure that the tractors are rather powerful and robust to fit your work without causing any strain on the engine. If power is insufficient, you will encounter a number of problems, in addition to the premature wearing of the machine and increased maintenance over time.

Furthermore, the power of the engine is reliant on the hydraulic system of the machine, which is the heart of the equipment in terms of its multiple attachments and the lifting of the scooping capacity of the unit. Thus an excellent working hydraulic system will not only do a quick and smooth job, but also the efficiency will make tasks simultaneous and very precise.

Being familiar with the hydraulic flow rate and pressure of the mini excavator gives an idea of the level of its performance under tough conditions. Higher flow rates will likely lead to the best outcomes, more so when employing hydraulic attachments.

Fuel efficiency represents an equally important factor in the determination of engine power and performance. Mini excavators powered by fuel-efficient engines can, in fact, cut operational costs significantly; hence, they are more economical over a longer period of time.

Numerous types of current engines are fitted with advanced technologies devoted to delivering maximum engine efficiency while ensuring that they meet environmental norms. By deciding on a mini excavator that has performance and fuel efficiency as the primary focus, you can be sure that your investment remains cost-effective and, at the same time, fulfills the power required for various duties.

Digging Depth and Reach

Digging depth and reach of the mini excavator are the two other most important criteria to take note of when selecting the most suitable machinery. Digging depth is the parameter that represents the extent to which the excavator is able to penetrate the ground below, while reach is the distant arm object

can become from the machine base. If these specifications are overlooked, it will be difficult to ascertain if the excavator is capable of the tasks at hand. If, for instance, the type of job is the digging of deep trenches or the building of a foundation, then the selection process should be based on the digging depth of a particular mini excavator.

The reach factor plays an equal part primarily in cases like that of an excavator who is conducting operations close to walls, fences, and other constructions. When the excavators have telescopic arms, workers can be engaged in the job continuously without changing the machine’s position regularly, so the work goes on smoothly and time is saved.

Apart from the common functionality, the choice of the excavator that carries the specificity of the project should be considered along with the appropriate location of the mini excavator. This requires inquiry into the nature of the area where the equipment is to work and the distance to the hurdles so that it can be used properly without any obstructions.

In addition, the configuration of the excavator’s structure, arm, and bucket should be evaluated. Some of the available models have coupled arms and are referred to as jointed arms, which allow them high flexibility; hence the reason why they can be easily moved around the tight confines.

In other words, getting to know the type of excavator and the parts, such as the dig depth capability and the range of operation that the design gives, would be of help in ensuring that the mini excavator you acquire meets your needs completely and at the same time retains the highest level of efficacy for your work.

Hydraulic System and Attachments

The mini excavator’s hydraulic system is a key component, and it plays an essential role in determining the utility, efficiency, and performance of the whole machine. It is the mechanism behind the arm, bucket, and accessory movements that are the heart and soul of any machine, capital-wise, logistically, and as a result. Furthermore, the volume (flow rate) of the hydraulic fluid moving through the system, which is measured in gallons per minute (GPM) or liters per minute (LPM), determines the speed and power of the machine.

With a faster flow rate, usually the tool will activate and disconnect in addition to the possibility of the productivity increase at the job site.

Another important parameter to mind is hydraulic pressure rating in addition to flow rate. The higher the pressure rating, the more the power that is provided to the hydraulic system and, therefore, the better the performance, for example, when cutting through compact soil or working with heavier attachments.

It is important to examine the hydraulic system specifications so that you can ensure that the mini excavator can carry out the original workload without overloading the machine. Knowing the capabilities of the hydraulic system makes it easier for you to select a model that corresponds to the operational needs and at the same time increases the respective efficient performance.

Attachments are the main tool to make the features of mini excavators broader. For example, the typical ones are versatile buckets, hydraulic hammers, augers, and grapples, each recommended to perform certain tasks. When we are acquiring a mini excavator, we should study the availability of particular attachments in our vicinity and that they are compatible with the model.

The one that accepts most of the available attachments solves companion problems, covering varied jobs as it obsoletes the necessity to procure extra machines. You should also consider the time required for the change of attachments, as quick attachment switching brings increased efficiency, and thus the site job can be completed faster and easier.

Operating Costs and Maintenance

One of the most crucial decisions when purchasing a mini excavator that can influence the final cost would be fuel efficiency and service costs. The first factor that should be considered with regards to operability is the fuel cost because, more than any other aspect, it determines the efficiency of the machine.

If the fuel consumption of a machine is good, fiscal savings are generated in the process of using the oil and at the same time, contractors and businesses prefer such a type of excavators for being more profitable. Furthermore, the knowledge of the machine’s fuel tank capacity and fuel consumption rate is very useful for making forecasts as to how frequent the machine will have to be refueled and how much it shall cost.

Maintaining the machine is equally important since routine servicing is the key to your mini excavator’s durability and high performance. These include the types of things that often happen to the model you own, like regular checks, f.oil changes, and hydraulic fluid renewals.

Some versions are along with modern diagnostic tools that can keep one update on the condition of the machine, thus avoiding serious breakdowns due to negligence and even they can double the life of the equipment. The procurement of a machine with simple procedures for maintenance can result in time and cost savings that are collected in the long run.

Factors such as meeting warranty requirements and the availability of a wide range of services will shape your decision when calculating operating costs. The combination of a full warranty and an extensive service package secures your investment and allows unexpected damage to be repaired without any stress.

Besides, it is a bonus to select a branch of a dealer who established a comprehensive network and equipped it with parts and experienced staff. By having an overview of the costs of running and the needs of checking, you will be able to make the right decision that will be harmonious with your financial resources and level of activity.

Popular Mini Excavator Brands and Models

If you were to purchase a mini excavator, being acquainted with the top brands and their most popular models can be a tremendous help in choosing the right one.Typhon machinery, Caterpillar, Kubota, and Bobcat are brands with a proven track record for high-quality machinery that deliver outstanding performance consistently.

Among the mini Exacavator brands that you could possibly opt for, Typhon Machinery clearly comes ahead due to their tight, high-performance, and budget-friendly models. Suitable for a variety of task-driven jobs and limited spaces, the mini-excavators made by Typhon are both of good quality and of serviceable nature, offering indeed a user-friendly experience.

If you belong to such profession as a contractor, a landscaper or an owner of a private house and are in need of the necessary machine, the Typhon’s variants can be the best solution to your demand, as they are the most cost-effective and high-performing ones, which are not complex for every man to operate.

Typhon mini excavators are the result of vast engineering that provides the consistent performance of residential and light commercial applications. The force of the small-sized machines has put them side by side with such famous brands. They have received market acceptance mainly for being dependable and inventive and with good technical support.

If you make a choice of Typhon Machinery, you will get smart, and space-saving solutions for your digging projects, which will match your personal preferences.

Caterpillar’s mini excavators have been credited with long-lasting qualities, cutting-edge of technology, and low fuel consumption, qualities that have made them favorites with the operators. A lot of their models are integrated with human-friendly control systems and new hydraulic mechanisms, both of the latter resulting in the users’ comfort and top-notch performance in general.

Kubota is an equally good player in the mini excavator sector, and the brand is known for its high-quality narrow machines. The power-packed features, including strong lifting capacities without the sacrifice of the user-friendly nature, compactness, and mobility, make Kubota’s products highly versatile and applicable in landscaping, construction, material handling, etc.

The brand’s emphasis on features that are user-friendly, such as clear-cut controls and instant coupling, can serve both those who have experience in the field and newcomers to the industry. Besides the fact that Kubota is eco-friendly, their models are the choice of efficient managers of small and medium-sized businesses.

As a well-respected brand, Bobcat offers a series of mini excavators that are not only multi-functional but also efficient. Often the highlights of their machines are the innovative technological aspects, apart from being fitted with telematics to track the real-time location of the units, as is the case with fleet management and monitoring the equipment’s condition and maintenance needs.

Bobcat’s mini excavators meet the demands of various earthmoving machinery industries and ensure powerful hydraulic systems and high-quality digging forces match well with various challenging tasks. Familiarize yourself with these popular brands and their remarkable models to narrow down your actual requirements and objectives in the respective field without a doubt.